Category

2L Rubber Machinery Mixer Banbury Laboratory Internal Mixer for EVA and PVC

Overview 2L Rubber Machinery Mixer Banbury Laboratory Internal Mixer for EVA and PVC Product Parameters Product Descript

Basic Info

| Model NO. | 2L |

| Key | Rubber Machinery |

| Mechanical Weight | 800kg |

| Capacity | 2L |

| Application | Rubber Products |

| Transport Package | Standard Export Wooden Box |

| Specification | customized |

| Origin | China |

| Production Capacity | 500PCS/Month |

Product Description

2L Rubber Machinery Mixer Banbury Laboratory Internal Mixer for EVA and PVC Product Parameters| Name | internal mixer |

| Capacity | 2L |

| Drive motor | 3.75KW |

| Rotation motor | 400W |

| Rolling angle | 110 |

| Output | 1.5-2.8KG/time |

| Weight | 800KG |

| Size | 1660 * 900 * * 2000mm |

Application

2L Internal Mixer | Experimental Internal Mixer | Small internal mixers are widely used as raw materials for rubber and plastic products such as EVA, PVC, TPR, PE, PP, PC metal powder, ceramic powder, functional masterbatch, rubber additives, shoe materials, rubber tires, sealing miscellaneous parts, electronic products, wires and cables, automotive products, and other rubber and plastic products.Working PrincipleWhen 2L internal mixer | small internal mixer | 2L internal mixer is working, the two rotors rotate relative to each other, trapping the material from the charging port into the roller gap, which is squeezed and sheared by the rotor. After passing through the roller gap, it encounters the lower top bolt sharp edge and is divided into two parts, respectively, along the gap between the front and rear chamber walls and the rotor, and then returns to the top of the roller gap. During the flow around the rotor, the material is subjected to shear and friction action everywhere, resulting in a sharp rise in the temperature of the rubber material and a decrease in viscosity, increasing the wettability of the rubber on the surface of the compounding agent, making the rubber fully contact with the surface of the compounding agent. The mixing agent agglomerates pass through the gap between the rotor and the rotor, the gap between the rotor and the upper and lower top bolts, and the gap between the internal mixing chamber walls together with the rubber, and are sheared and broken, surrounded by stretched and deformed rubber, and stabilized in a broken state. At the same time, the convex ribs on the rotor cause the rubber material to move along the axial direction of the rotor, playing a stirring and mixing role, ensuring that the mixture is evenly mixed in the rubber material. The compound is sheared and broken repeatedly in this way, and the compound is deformed and restored repeatedly. The rotor ridge is continuously stirred, so that the compound is evenly dispersed in the compound and reaches a certain Dispersity. Due to the much greater shear action on the rubber during mixing in the internal mixer than in the open mixer, and the high mixing temperature, the efficiency of rubber mixing in the internal mixer is significantly higher than that in the open mixer.

Technical Characteristics2L Internal Mixer | Small Internal Mixer | 2L Internal Mixer features small footprint, energy saving, safety, easy operation, good dispersion, low noise, long service life, extremely low maintenance frequency, built-in dust collector, all technology from Taiwan, and core accessories imported and purchased. The 2L internal mixer is one of the small internal mixers with high accuracy, enabling material formulators to more accurately grasp the changes and characteristics of materials. Small internal mixer is designated and selected by many domestic institutions, and has established long-term cooperative relationships with more than 30 institutions nationwide. For example, Tsinghua University, Chinese Academy of Sciences, South China University of Technology, Nanjing University, Xi'an University, Xi'an Jiaotong University, Harbin University of Technology, Shanghai University, Central South University, Xiamen University, Yueyang Baling Petrochemical, Beijing Yanshan Petrochemical, Zibo Qixiang Tengda Chemical, Tianjin Petrochemical, China Academy of Engineering Physics, Wuhan Wangrui Laboratory, Koton Polymer and many other well-known institutions.Company Profile

Xiamen Webron is a national high-tech enterprise, a star enterprise in Fujian Province, and a well-known innovative technology research and development enterprise. It was registered in the Cross-Strait Equity Trading Center in 2021, with the enterprise code of 867467; The headquarters is located in the Tsinghua Strait Research Institute. It is a 3A credit enterprise in China, a member unit of the Mechanical Mold Branch of the China Rubber Industry Association, a key recommended private enterprise in Fujian Province, and a member unit of the Fujian Plastic Industry Association; Signed contracts with 15 professors in the fields of polymer, metal, and ceramics, has industry-university-research cooperation with multiple universities, and has joint laboratories with universities; It is a metal ceramic rubber plastic machinery technology enterprise specializing in research and development, design, manufacturing and sales, and after-sales maintenance services. Company Vision: Let China's mixing technology synchronize with the world. Serving new material enterprises such as polymer materials, graphene materials, advanced ceramics, and powder metallurgy, our core products include torque rheometers, rubber internal mixers, metal internal mixers, ceramic internal mixers, internal mixing and granulation integrated machines, open mills, twin screw extruders, and plate vulcanizers.

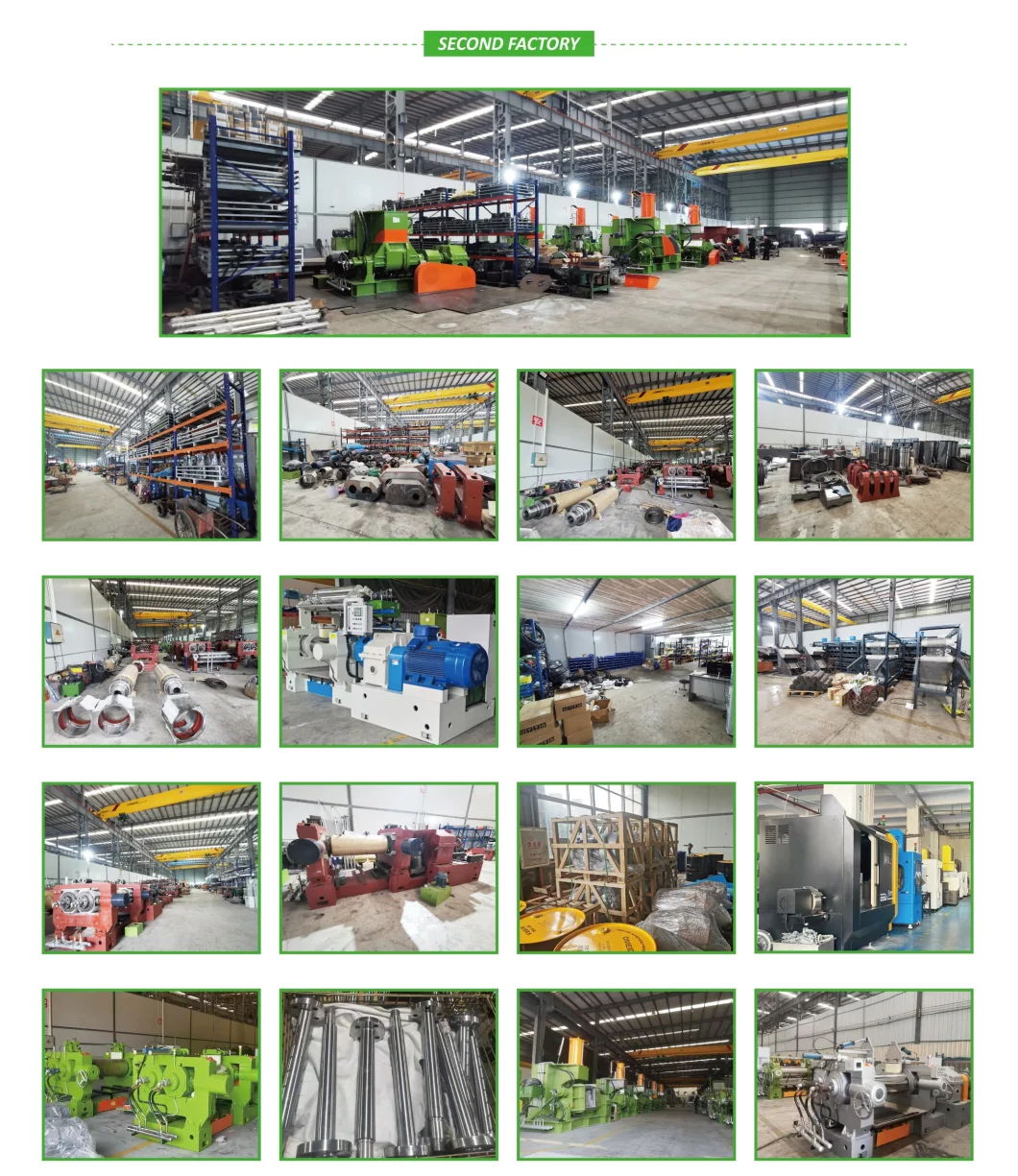

The company has successively passed the certification of ISO 9001, intellectual property management system, and high-tech products. It has strong production capacity and advanced technological processing equipment, such as 10 five-axis CNC machining centers, 4 CNC lathes, 5 slow moving wire and other imported processing equipment. The company has independent laboratories, and various materials and experimental equipment are provided to customers for visiting/testing formulas/proofing. The professional R&D and design team can meet the special non-standard requirements of customers and customize the model, which has been recognized and praised by the majority of customers.

Since its establishment, Webron has worked hard, innovated, and made progress. The company promises to produce high-quality products for you with specialized technology, and to create higher value for you with high-tech achievements! Xiamen Webron Technology is willing to work with you to create a brilliant future!

Q1. How to choose the most suitable Mechanical Equipment ?

A1:Our professional team will give you the best suggestion as long as you tell us what kind of test you need to do andthe required specification.

Q2. What's the delivery term?

A2:At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15~20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

Q3. Do you accept customization service?

A3:Yes, of course, we can not only offer standard machines, but also customized machines

according to your request. Don't hesitate to tell us your requirement, we will try our best to meet your needs.

Q4. Can we visit your factory before order?

A4:Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

Q5. How about your warranty?

A5:1. Provide on-site installation guidance;

2. Responsible for on-site commissioning and trial run of the supplied equipment until it passes the acceptance;

3. Responsible for on-site operation and maintenance training for Party A's personnel;

4. The unit is warranted free of charge for one year under correct use, and the supply of spare parts is guaranteed for a long time;

5. Provide long-term free technical service consultation;

6. Within and outside the warranty period, the supplier shall provide clear solutions within 3 hours after receiving the buyer's equipment failure notification