300L Hydraulic Tilt Discharge Double Sigma Blade Mixer to Process High Viscosity Material

Basic Info

| Model NO. | 5L 10L 15L 30L 50L 100L 500L 1000L 2000L 3000L |

| Application Area | Chemical |

| Layout Type | Horizontal |

| Mixing Drum Shape | Sigma |

| Additional Capabilities | Mixing |

| Operating type | Continuous Operating |

| Condition | New |

| Dimension | Customer |

| Application Scope | Viscous Fluid |

| Capacity | 5-3000L |

| Transport Package | Three-Layer Plywood |

| Specification | 5L 10L 100L 500L 1000L 2000L 3000L |

| Trademark | KEDA |

| Origin | China |

| HS Code | 8479820090 |

| Production Capacity | 10set/Month |

Product Description

We will offer you price referring to your detail request, so please kindly inform us of the material, viscosity, density, etc, andother requirements you prefer, and the special offer will be given.

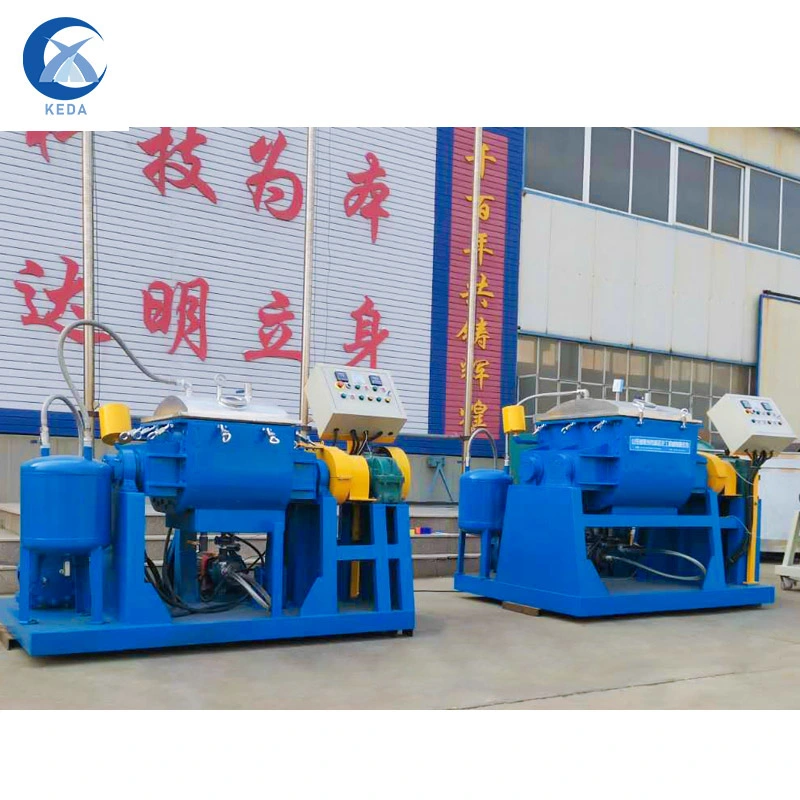

The pictures are above just for your reference.

Our machines can be customized, leave an inquiry to know more details about price, packing, shipping and price.Any questions, feel free to contact us.

Lusa Ti

| specification | 5L | 10L | 100L | 300L | 500L | 1000L | 1500L | 2000L | 3000L | |||

| Effective volume L | 5 | 10 | 100 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | |||

| Feeding amount L | 3.5 | 7 | 70 | 210 | 350 | 700 | 1100 | 2100 | ||||

| Main motor power Kw | 1.1-1.5 | 4-7.5 | 7.5-18.5 | 15-30 | 18.5-45 | 22-55 | 37-75 | 45-110 | ||||

| Screw motor power Kw | NO | 3-4 | 3-4 | 4-5.5 | 5.5-7.5 | 7.5-11 | 11-15 | |||||

| Dischargethe way | High temperature | Manually turn cylinder | Hydraulic cylinder | |||||||||

| Other type | Manually turn cylinder | Hydraulic cylinder | Hydraulic turn cylinder, screw discharge, the next material | |||||||||

| Mixing speed r/min | 33/23 | 35/22 | 37/21 | 35/25 | 30/16 | |||||||

| Heating the way | High temperature | no | electricity | |||||||||

| Other type | Electricity/steam | |||||||||||

| Electric heating power Kw | HT | 6-10 | 8-10 | 12-15 | 30-35 | 35-45 | 60-80 | 90-110 | 110-140 | 160-190 | ||

| OTHER | 1.8 | 1.8 | 4.2 | 12 | 18 | 24 | 36 | 36-54 | 54-72 | |||

| Steam pressure Mpa | 0.3 | |||||||||||

| Vacuum type vacuum | -0.090Mpa | |||||||||||

| Pressure type pressure MPa | 0.45 | 0.35 | ||||||||||

| Dimension mm | ordinary | L | 1100 | 1100 | 1600 | 2150 | 2550 | 2750 | 3030 | 3060 | ||

| W | 410 | 410 | 610 | 850 | 1000 | 1200 | 1850 | 2250 | ||||

| H | 510 | 510 | 1360 | 1300 | 1550 | 1800 | 1850 | 2070 | ||||

| vacuum | L | 1100 | 1100 | 1600 | 2150 | 2550 | 2750 | 3030 | 3100 | |||

| W | 1000 | 1000 | 610 | 1250 | 1320 | 1600 | 2150 | 2350 | ||||

| H | 520 | 520 | 1360 | 1400 | 1550 | 1800 | 1850 | 2070 | ||||

| Weight kg | 210~300 | 250~340 | 1100~1250 | 2000~2200 | 2800~3000 | 4200~4500 | 5200~5500 | 6400~6800 | 9000~9500 | |||

| Table parameters for reference only, according to customer requirements can be designed (a variety of volume, speed and special requirements) dedicated models | ||||||||||||

300L Hydraulic Tilt Discharge Double Sigma Blade Mixer to Process High Viscosity Material

The Sigma mixer is consist of mixing chamber ,frame support ,hydraulic system ,electric control system, Discharge system And two Z shape blade in the chamber drove by the motor and the two blade rotating with different speed ,but can be control by the inverter .The sigma blade mixer caused by a pair of mutually cooperating and rotating Z blades to produce a strong shearing action so that the semi-dry state or the rubbery viscous plastic material enables the material to react quickly to obtain a uniform mixing.

Independent distribution box (control panel), which can realize separate and precise control of stirring speed, heating or cooling temperature, stirring and discharging system.

Three Discharge methods facilitate processing of different materials.

FAQ

Q: Do you have machines in stock?

A: Yes, but just the small-scale machines. Machines are different with other products, most of the large-scale machines are designed according to our customers' requirements, different customers have different production requirements, so the technical parameter is different for most machines. On the other hands, most of the our machines will cover a large area, so once the machines are finished, we will effect shipment after QC.

Q: Can you send the detailed drawings of the machine to us before we place order?

A: We can send you a draft drawing of the machines, and after you place order and pay the deposit, our engineer will design the specific technical parameters for you and send you the detailed drawings. Once you confirm without questions, we will put it into production.

Q: Can we pay the balance after we receive the machines and test without problems?

A: It's unnessary to worry about the quality of our machines, we are confident in that. After the machine is finished, we can install and test the machine for you (if you can not come to our factory, we can record a vedio and send to you). Only after you check without problems, we will effect shipment.

Contact to me