Best Price 7.5kw 400L Hydraulic Lifting Platform Type Emulsion Latex Paint Mixer Machine High Speed Disperser

Basic Info

| Model NO. | ACE-TSJ-M13 |

| Application Area | Chemical |

| Layout Type | Verticle |

| Mixing Drum Shape | Disc |

| Additional Capabilities | Milling |

| Operating type | Cycle Operating |

| Condition | New |

| Material | SS304/SS316(L) |

| Power | 0.75-22kw |

| Voltage | 110V/220V/380V, Customized |

| Speed | 0-3600rpm |

| Motor | Domestic, ABB/Siemens |

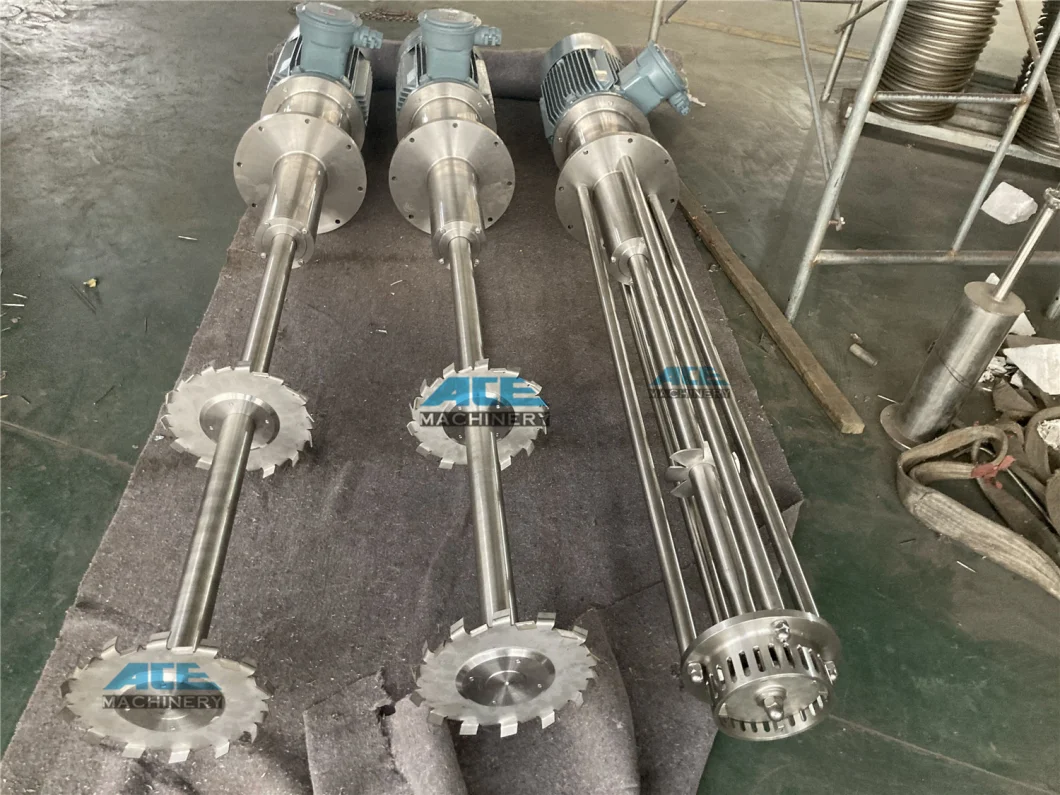

| Impeller | Stator/Rotor |

| Transport Package | Standard Export Packing |

| Specification | Customized |

| Trademark | Wenzhou Ace Machinery |

| Origin | Wenzhou, Zhejiang, China |

| HS Code | 8474390000 |

| Production Capacity | 50sets Per Month |

Product Description

20 Years Of Experience. Reasonable Price And Best Service, CE Certificated Products.7-15 days fast delivery. Please contact us for the offer.

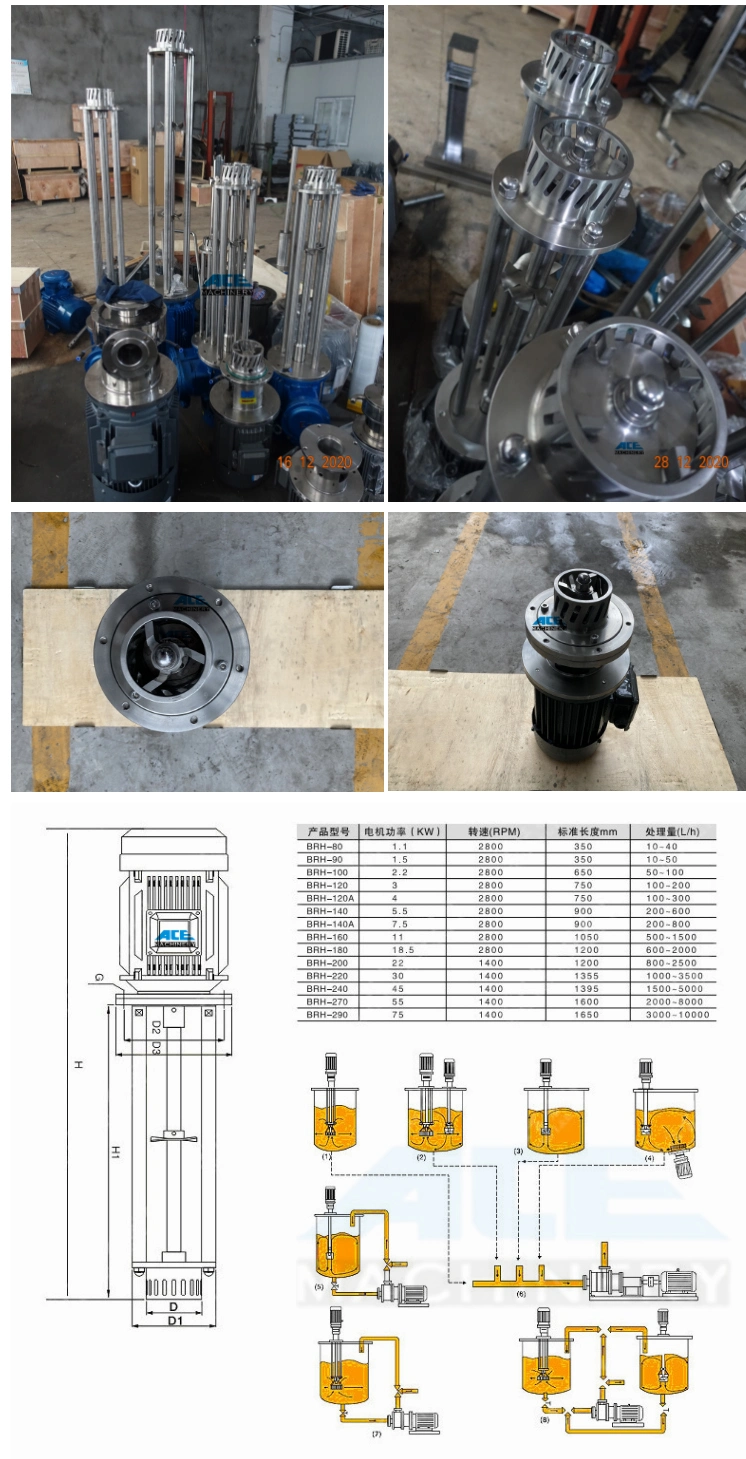

Product DescriptionDescription:High shear emulsifier mixer is efficient, rapid and uniform a phase or more of the phase distribution to another continuous phase, and in the usual case each phases are mutually insoluble. Due to the rotor is generated by high speed rotation high tangent speed and high frequency mechanical effect bring strong kinetic energy, so that immiscibility of solid phase,liquid phase and gas phase in the corresponding mature technology and right amount under the common function of additives, the instant uniform fine disperse emulsion, after high frequency move in circles, ultimately get the steady and high quality products.This series of machines are: support frame, motor, homogenizing head, cylinder, electrical control systems and control devices. Compact, easy to install, clean and generous appearance.Homogeneous pinion lift off with pneumatic type, up off the smooth and flexible. Homogeneous gear shaft and main parts are all made of stainless steel, wear resistance, corrosion resistance, excellent quality and long service life, smooth operation, low noise, any rise in the operation down, according to material viscosity, speed arbitrary regulation to prevent the material flying, dispersion impeller for a variety of materials.Installation method is flexible to adapt to a variety of venues operation is extremely simple, easy maintenance, strong and beautiful body. Advanced features, easy to operate, safe facilities will bring your work pleasant.According to different output requirements, there are multiple models with different motor powers as selected. Such as 2.2kw,4kw,5.5kw,7.5kw etc

Remark: 1. You can use your own storage tank, just please tell us your tank size before order. Or we can provide a storage tank separately. 2. If you have special requirements for the material, stirring paddle, mixing speed or dimension, please contact us freely.

There are three lifting method:Pneumatic lifting, Electric lifting and Manual lifting.

Laboratory homogenizerDescription:

It is suitable for the mixing, emulsification of liquid/liquid, such as biological, physical and chemical, cosmetics, health care products, food, etc., and the field of dispersion, homogenization and slurrying of liquid/solid powder. It is an ideal experimental equipment for scientific research, product development, quality control and production process application in scientific research institutions, colleges and universities, health and epidemic prevention and product manufacturing.

High shear mixerDescription:

high shear emulsifier mixer,it's widely applied in the beverage, food, dairy, pharmaceutical, chemical and process industries used with tank or shelf, can shearing, mixing and homogenizing products.

| Material | SS304 or SS316L | ||

| Capacity | 0-10T (Customized) | ||

| Tank inside pressure | Normal | ||

| Viscosity | 1-1000000pas | ||

| Rotors teeth | strip type round type etc | ||

| Temperature | 0-100 celsius degree | ||

| Installation | Movebale or Fixed or Lifting | ||

| Connection | Flange at the top of the tank | ||

| Motor type | Normal | Ex-proof | inverter |

| Speed | 0-3400RPM | ||

The tank is capable of distributing one or more phases to another continuous phase efficiently, quickly and uniformly, in which case the phases are mutually insoluble. Due to the high tangential speed and high-frequency mechanical effects generated by the high-speed rotation of the rotor, the material is subjected to strong mechanical and hydraulic shear, centrifugal extrusion,liquid layer friction and impact in the narrow gap between the stator and the rotor. A combination of tearing and turbulence. Therefore, the incompatible solid phase, the liquid phase, and the gas phase are uniformly and finely dispersed and emulsified under the action of the corresponding mature process and an appropriate amount of additives, and the high-frequency cycle reciprocates to finally obtain a stable high-quality product.

| High shear emulsifying tank (Accept customized) | |||

| Profile/type | Single layer tank | Double layer tank | Three layer tank |

| Material | SS304 or SS316L | ||

| Volume | 50L-30T (Customized) | ||

| Pressure | Vacuum-1Mpa | ||

| Tank Type | Vertical type/Horizontal type/Mobile type | ||

| Structure | one layer | Inner layer+jacket | inner layer+jacket+insulation |

| heating way | Electric/Steam Heating | ||

| Inside Finsh | Mirror polished Ra<0.4um | ||

| Outside Finish | 2B or Satin Finish | ||

| Stirrer type | impeller, Anchor , Turbine , High shear, magnetic mixer, Anchor mixer with scraper | ||

| Power | 0.55~55KW | ||

| Voltage | 110V~480V | ||

| Top Head type | Dish top, Open lid top, Flat top | ||

| Bottom type | Dish bottom, Conical bottom, Flat bottom | ||

| PARTS DETAILS | 1.Quick open manhole / Pressure manhole | ||

| 2.Various types of CIP cleaners | |||

| 3.Sterile respirator | |||

| 4.Adjustable Legs | |||

| 5.Inlet and Outlet sanitary valve | |||

| 6.Thermometer (According to customer requirements ) | |||

| 7.Paddle blender .(According to customer requirements) | |||

| 8.Liquid level meter and lever controller (According to customer requirements) | |||

| 9.Ladder | |||

| Application | Food, Beverage, pharmacy, biological,honey, chocolate, alcohol ,chemical industry etc | ||

| We can customize the equipment according to customer requirements. | |||

| Q | Are you trade or manufacturer? | |||

| A | We are a factory with an international sales company specialized in support for global distributors. | |||

| Q | Can you provide instant technical consulting services? | |||

| A | We are able to discuss technical details and offer suggestions over the phone in English. You can get the answers in minutes, instead of days. | |||

| Q | What's the difference between Ready-To-Ship and Customized products? | |||

| A | Some of RTS standard products are in stock and ready to ship in 2-3 days. We can also quick design and make the drawings for customer requirements, then begin the production. | |||

| Q | What is the payment terms? | |||

| A | We accept Alibaba Trade Assurance Order, also can T/T and L/C. | |||

| Q | How to choose the shipment way? | |||

| A | It is according to the order quantity, delivery time, costs and customs policy etc. (Or decide by customers) | |||

| Q | How about the after-sales service? | |||

| A | Fast after-sales support. Our products have a one-year warranty and free permanent consulting services. | |||