Category

Cosmetic Homogenizer Emulsifing High Speed Disperser for Body Moisturizer

Cosmetic Homogenizer Emulsifing High Speed Disperser for Body Moisturizer INTRODUCTION: The PerMix PD series High Speed

Basic Info

| Model NO. | PD |

| Layout Type | Verticle |

| Mixing Drum Shape | Conical |

| Additional Capabilities | Milling |

| Operating type | Cycle Operating |

| Condition | New |

| Contact Parts | Stainless Steel |

| Transport Package | Wooden Crates |

| Specification | CE |

| Trademark | PerMix |

| Origin | China |

| HS Code | 8479820090 |

| Production Capacity | 100 PCS/Year |

Product Description

Cosmetic Homogenizer Emulsifing High Speed Disperser for Body MoisturizerINTRODUCTION:

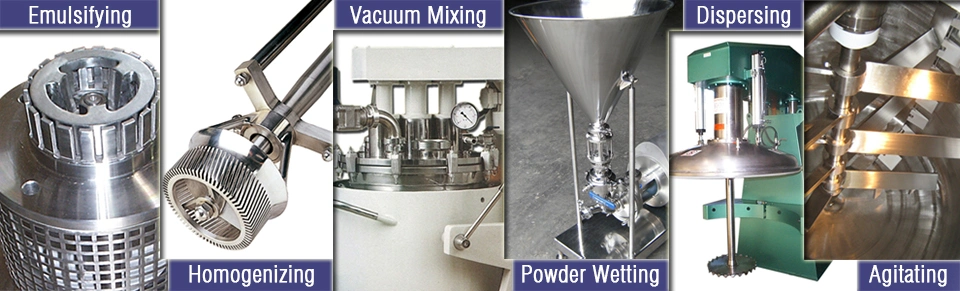

The PerMix PD series High Speed Disperser is ideally designed to meet the demands of a broad spectrum of industrial applications. The PerMix PD series High Speed Disperser is featured by its ease of operation and high efficiency to reduce a lot of cost and operation time, and has proven itself by providing the most economical solutions to a variety of dispersing problems.

HIGH SPEED DISPERSERS FOR SPECIFIC USES:

PerMix's VACUUM High Speed Disperser produces an intense motion which rapidly removes air or gases from the product. The built-in vacuum cover lifting device enables you to adjust the PD series High Speed Disperser disc height without breaking the vacuum.

The PerMix TWIN-SHAFT High Speed Disperser exclusively combines a slow running element with a dissolver impeller enables you to produce batches of excellent quality and uniformity, which are twice as large as those produced in a conventional system. This mixer can handle high viscosity products (up to 600, 000 CPS) or large quantities of solids.

A vacuum version of the TWIN-SHAFT High Speed Disperser is also available as well as different types of slow running elements.

PerMix WALL-MOUNTED High Speed Disperser is a practical and economical way to produce small and medium sized batches. A counterweight helps elevate the mixer, which can then be locked in any desired position. As an option, the elevating system can be manually, electro-mechanically or hydraulically controlled.

PerMix Lab-size High Speed Disperser is used for R&D purposes by performing each of the previously mentioned functions.

SPECIAL FEATURES:

PerMix is able to customize accessories for PerMix PD series High Speed Disperser to meet your specific needs. For example:

1. A swiveling head which can serve several stationary drums

2. A quick locking vacuum cover which allows easy dismantling

3. An adjustable safety cover which protects against splashing and dust

4. An impeller system with a static toothed ring for very high shearing forces

5. Mixing drums

6. Double-jacketed mixing drums

7. Individually driven scrapers

APPLICATIONS:

Applications of the PerMix PD series High Speed Disperser include but are not limited to:

1. General: Dispersing, suspending, emulsifying, dissolving, homogenizing, mixing and breaking down agglomerates of high viscous materials (up to 300, 000 CPS)

2. Paints, varnishes and printing inks: Preparing paint batches, carbon paper paint, artist's paints, priming and rust removing paints, fillers, dispersion and coating paints, varnish pastes, printing inks, resin solutions, textile printing inks, etc

3. Plastics: Preparing all types of PVC, PU pastes, color concentrates and plastic putties

4. Adhesives: Preparing rubber, neoprene, resin and other types of adhesives

5. Chemicals: Preparing filler dispersions, coating materials, insulation materials, bitumen based sealing materials, greases and lubricants

| Model | Working Volume (*) (liter) | Main Motor (kW) | Shaft Speed (rpm) | Overall Dimension | Weight (kg) | ||||

| L (mm) | W (mm) | H (mm) | H (lifted) (mm) | Disc Dia. (mm) | |||||

| PD-300 | 300 | 11 | 400-2100 | 2200 | 1100 | 2100 | 3100 | 250/200 | 1200 |

| PD-500 | 500 | 15 | 380-2000 | 2200 | 1100 | 2100 | 3100 | 300/250 | 1300 |

| PD-700 | 700 | 22 | 330-1700 | 2400 | 1300 | 2200 | 3300 | 350/300 | 1400 |

| PD-1200 | 1200 | 30 | 290-1600 | 2800 | 1600 | 2500 | 3700 | 425/350 | 1900 |

| PD-2000 | 2000 | 37 | 300-1300 | 2800 | 1600 | 2500 | 3700 | 500/425 | 2100 |

| PD-3000 | 3000 | 55 | 300-1000 | 3400 | 2200 | 3000 | 4500 | 625/500 | 2400 |

| PD-4000 | 4000 | 75 | 280-900 | 3400 | 2200 | 3000 | 4500 | 700/625 | 2600 |

| PD-6000 | 6000 | 110 | 300-800 | 3800 | 2400 | 3200 | 4800 | 800/700 | 3100 |

2. All specifications and illustrations are as accurate as is reasonably possible, but they are not binding.

3. PerMix reserves the right to modify the design without notice.

FAQ:

Q: What is your price level compared with European suppliers and local Chinese suppliers?A: Depending on the machine type and size, our price level is 30%-60% less than the European suppliers and 5-15% higher than the big local suppliers.

Q: Are you able to provide tailor-made design and production for the mixers?

A: Yes, in fact more than half of our mixers are tailor made, which is one of our strong points.

Q: Are you able to design and produce other processing equipment?

A: We are open to discuss about it.

Q: Can you provide machines to OEM customers, meaning to label their brands on the machines.

A: Yes we are doing it a lot. We have several OEM partners in the USA.

Q: Do you have agent network out of China?

A: Yes we do have agents but only in some countries, for example in USA, Germany, Poland, Spain, Denmark, Turkey, Argentina, etc. We are still looking for more agents because we believe to work with agents is the best way to do business.

Q: What is your delivery lead time of the mixing equipment.

A: Depending on the size and level of customization, but usually it is from 6-14 weeks.

Q: How do you pack and ship the mixing machines?

A: For machines don't require full container loading, we will pack them in wooden case. For FCL (full container loading) shipment, we will just wrap the machines in plastic films and fix them in the container. The shipment can be either by air or by sea