Explosion-Proof Stainless Steel High-Speed Paint Disperser Water-Based Glue Paint Mixer

Basic Info

| Model NO. | FM-FS-22 |

| Certification | CE, ISO, GOST, SONCAP, CCC, API, SGS |

| Application Area | Chemical |

| Layout Type | Verticle |

| Mixing Drum Shape | Disc |

| Additional Capabilities | Milling, Drying, Granulating, Coating |

| Operating type | Continuous Operating |

| Condition | New |

| Power | 22kw |

| Transport Package | Wood Case |

| Specification | 10-5000L |

| Trademark | FAIR Machinery |

| Origin | Zhengzhou City, China |

| HS Code | 8479820090 |

| Production Capacity | 350 Sets |

Product Description

The liquid material mixer is specialized in liquid materials such as ink, glue, and paint. The lifting is free and the positioning is accurate. The customer can position the mixer blades in the upper, middle, and lower layers as needed to perform high-efficiency mixing.

| Model | Power (KW) | Capacity (L) | Disc Diam(mm) | Speed (rpm) | Stroke (mm) | Hydraulic Power (kW) |

| FM-FS-2.2 | 2.2 | 50-100 | 150 | 0-1440 | 600 | 0.75 |

| FM-FS-4 | 4 | 50-200 | 200 | 0-1440 | 600 | 0.75 |

| FM-FS-5.5 | 5.5 | 80-250 | 200 | 0-1440 | 800 | 0.75 |

| FM-FS-7.5 | 7.5 | 100-300 | 250 | 0-1440 | 800 | 0.75 |

| FM-FS-11 | 11 | 100-400 | 250 | 0-1440 | 800 | 0.75 |

| FM-FS-15 | 15 | 150-500 | 300 | 0-1440 | 800 | 0.75 |

| FM-FS-18.5 | 18.5 | 200-800 | 300 | 0-1440 | 1100 | 1.1 |

| FM-FS-S22 | 22 | 200-1000 | 300 | 0-1440 | 1100 | 1.1 |

| FM-FS-30 | 30 | 300-1500 | 350 | 0-1440 | 1100 | 1.1 |

| FM-FS-S37 | 37 | 400-2000 | 400 | 0-1440 | 1100 | 1.5 |

| FM-FS-45 | 45 | 500-2500 | 450 | 0-1440 | 1100 | 1.5 |

| FM-FS-55 | 55 | 600-3000 | 450 | 0-1440 | 1300 | 2.2 |

Lab disperser mixer by electric control lifting machinery, host frame, motor stirring, instrument speed control four parts, each part of the compact and reasonable structure.

The frequency conversion speed regulation is stable and powerful, suitable for various viscosity; hydraulic and mechanical lifting forms, lifting and rotating freely, adapt to various positions; common and explosion-proof configuration, safe and reliable, simple operation and maintenance; strong production continuity, for materials Rapid dispersion and dissolution, good dispersion effect, high production efficiency, stable operation and easy installation. There are different powers and models for the viscosity and throughput of different materials.

Mechanical lifting or hydraulic lifting, 360°c rotation, step-less speed regulation

High dispersing, mixing, stirring, dissolving, and homogenizing of liquid-liquid, liquid-powder materials

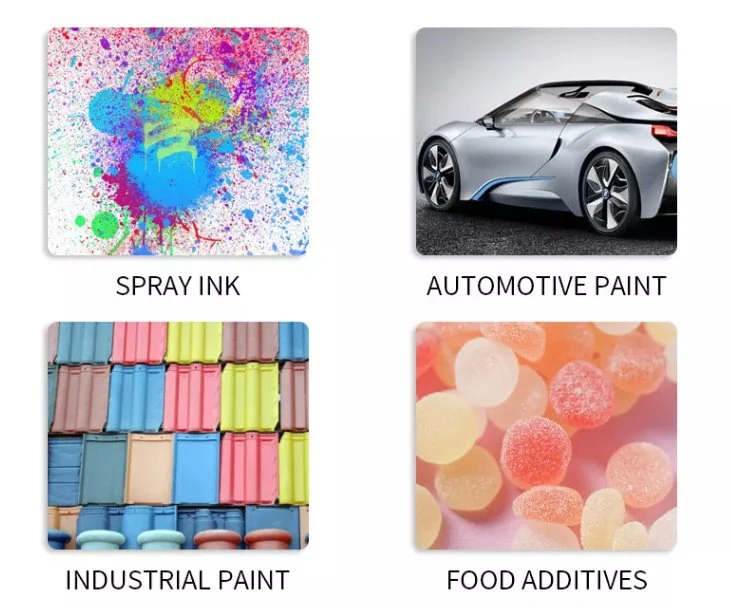

Application: Widely used in dispersing and mixing Paint, Coating, Pigment, Emulsion, Resin, Printing Ink, Adhesive, Dye, cosmetics, Petroleum, etc.

Q: What's your company's strength? Because I saw most products their appearance are very similar.

A: Yes, you are right, similarity in the appearance of products is indeed a question.

For this matter, we mainly do two aspects: First of all, insuring product quality; On the other hand, increase the professionalism of sales reps and improve their communication ability, to provide customers more extra value besides the product.

Q: How can I trust you? After all, this is our first cooperation, but I have to give you the money before you ship the goods.

A: Yes, it's really not easy to choose a reliable supplier among many suppliers.

High-quality food-grade speed adjustable paint mixer with low price is a variable speed disperser for paints, inks, paints, dyes, and other chemical industries, the food industry, and paper industry, for different kinds of liquid and solid materials for wet dispersion and stirring.

Working principles of high-speed dissolver:

Through the high-speed rotation dispersing disc, the material will become in an annular form flow, resulting in a strong vortex flow, which descends down to the bottom of the vortex in a spiral state. During the process, materials are dispersed, dissolved, mixed, and emulsified efficiently due to the strong shearing crash and friction among the particles.