Category

High Pressure Seeding Tank and Fermentation Vessel for Mycose

Description of Fermentation Tank/VesselFermentation Tank/Vessel (also as known as Fermentater) refers to an equipment us

Basic Info

| Model NO. | SDI-FJ |

| Heat Transfer Structure | Jacket/Coil (Per Application) |

| Automatic Grade | Per Urs |

| Condition | New |

| Interior Roughness | Less Then 0.4 μm |

| Transport Package | Wooden Pallet / Carton |

| Trademark | SDI |

| Origin | China |

| HS Code | 8479820090 |

| Production Capacity | 100 PC/ Year |

Product Description

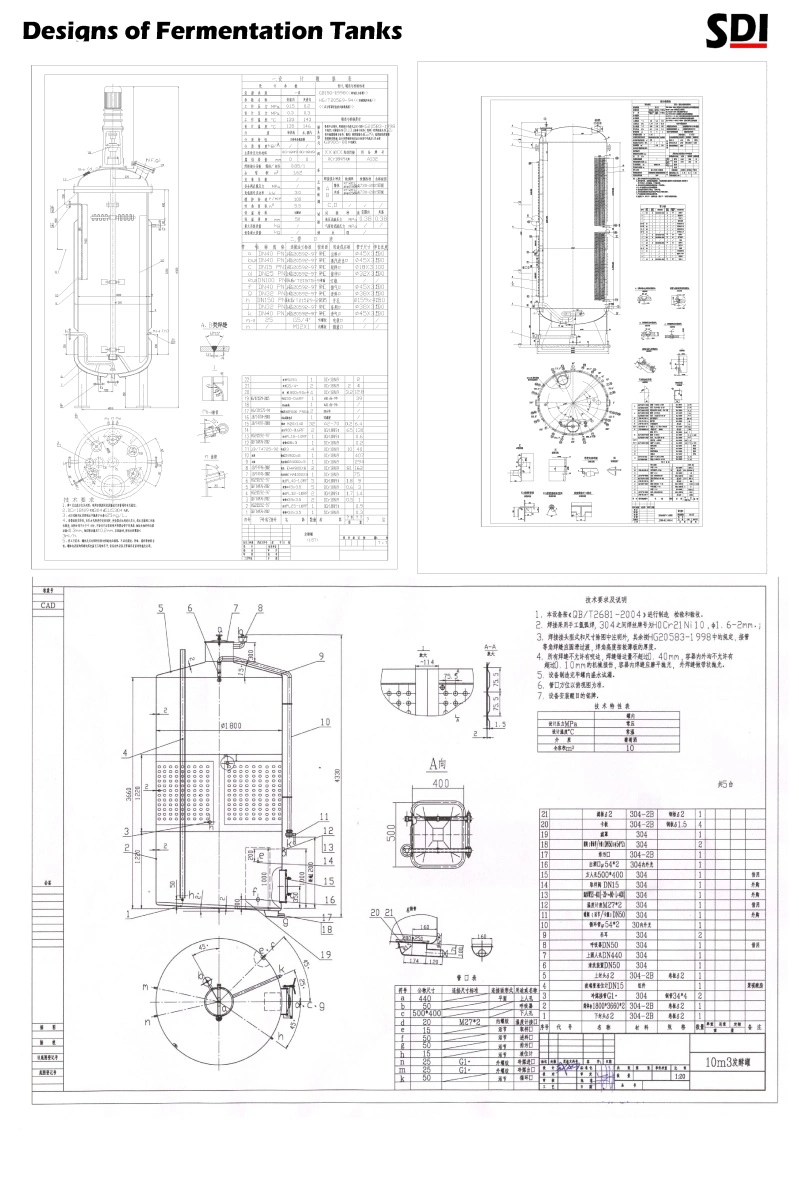

Description of Fermentation Tank/VesselFermentation Tank/Vessel (also as known as Fermentater) refers to an equipment used in the industries for microbial fermentation. The main body is generally a main cylinder made in all stainless steel and has volume from Hundreds of liters to Dozens of Thousands. Attention should be paid to the structure and rigor in design and processing. It can well withstand Steam Sterilization, has some operational flexibility and minimized internal accessories (in avoiding with Dead Angles/Corners) and also has strong Transfer Performance within Material and Energy, and shall be Easy For Cleaning.Application Ranges:Fermentation Tank/Vessel are widely used for facilitating the Fermentation of products like Yoghurt, Beer, Wine, Dairy, Amino Acid, Organic Acid, Beverage, Antibiotics and Fine Chemicals etc.Product Features:1. Online CIP cleaning, SIP sterilization (121 ° C / 0.1 MPa, subject to Customerization ).2.Designed according to the sanitary requirements, the structure design shall be very user-friendly and easy to operate.3. In appropriate Diameter Ratio, Customized Design with Stir, Cooling, Heating, Air-Breathing, CIP Port, Thermal Isolation etc. as per applications.4. Inner Side Finish: Mirror or Matt Polish, Ra<0.4um.5. Dead Angle Free.6. Pressure and Temperature Design: As per specific applications.| Fermentation tank | |||||||||

| Main technical parameters | |||||||||

| Product Model | FJ0.1 | FJ0.2 | FJ0.5 | FJ1 | FJ2 | FJ5 | FJ10 | FJ20 | FJ50 |

| Volume (L) | 100 | 200 | 500 | 1000 | 2000 | 5000 | 10000 | 20000 | 50000 |

| Diameter (mm) | 400 | 500 | 700 | 900 | 1200 | 1500 | 1800 | 2300 | 3100 |

| Height (mm) | 2000 | 2300 | 2650 | 2900 | 3800 | 4480 | 5250 | 6550 | 8550 |

| Pressure in tank (MPa) | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Pressure in jacket (MPa) | 0.3 | 0.3 | 0.3 | 0.2 | 0.3 | 0.3 | Pipe 0.3 | Pipe 0.3 | Pipe 0.3 |

| Number of blending paddles | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 4 | 4 |

| Blending rotation speed (r/min) | 400 | 360 | 265 | 220 | 180 | 160 | 145 | 125 | 110 |

| Motor power (kw) | 0.55 | 0.75 | 1.1 | 1.5 | 3 | 5.5 | 7.5 | 7.5 | 11 |

| Cooling mode | Jacket | Equipped with coiled heat exchanger | |||||||

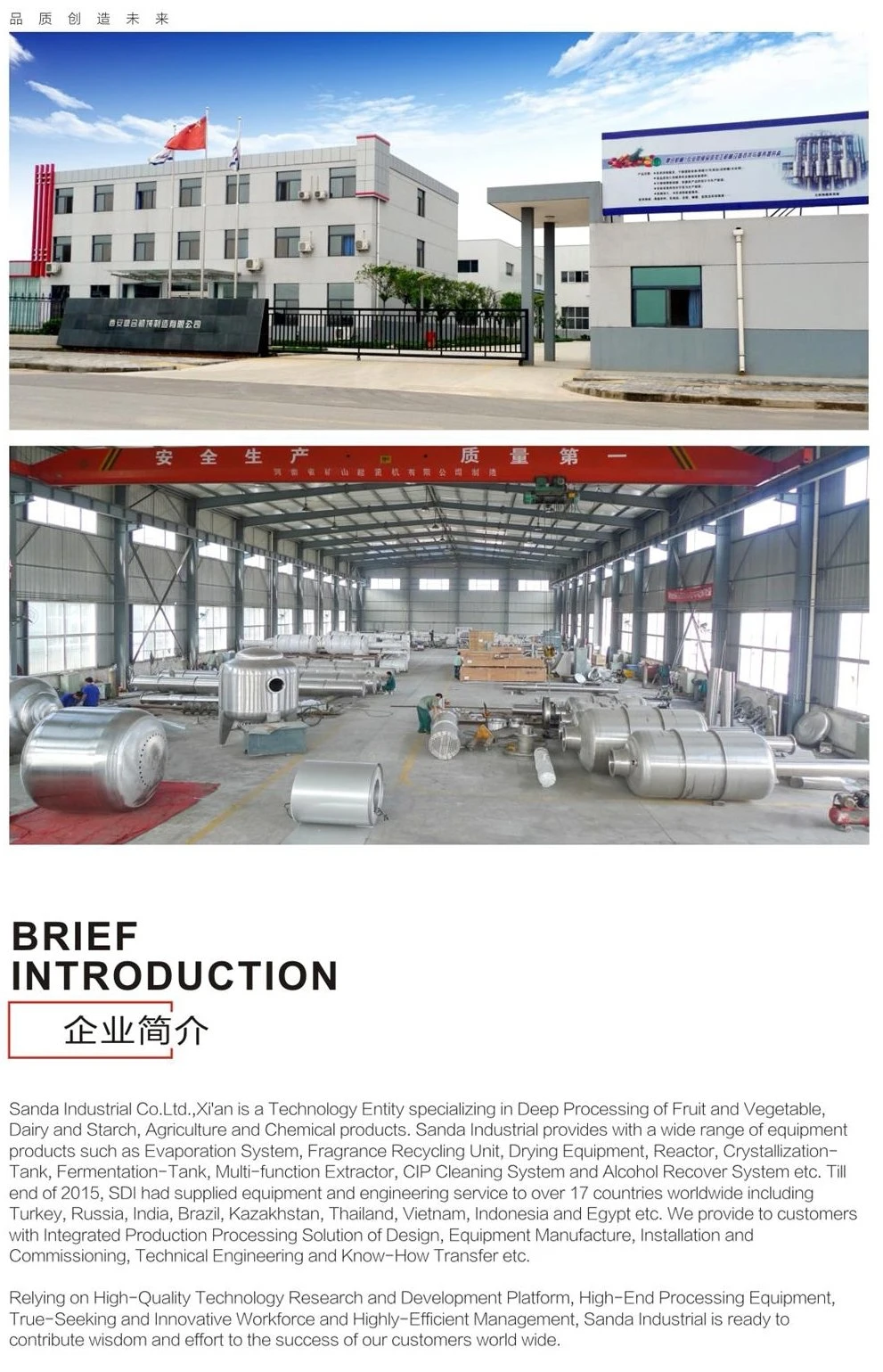

ABOUT US --- SANDA INDUSTRIAL