High Quality Stability Disperser Paint Ink Coating Disperser Manufacturer

Basic Info

| Model NO. | JFD |

| After-sales Service | Pre-Sale, in-Sale, After-Sale |

| Warranty | 1 Year After Installation |

| Mixer Type | Agitator |

| Working | High Speed Mixer |

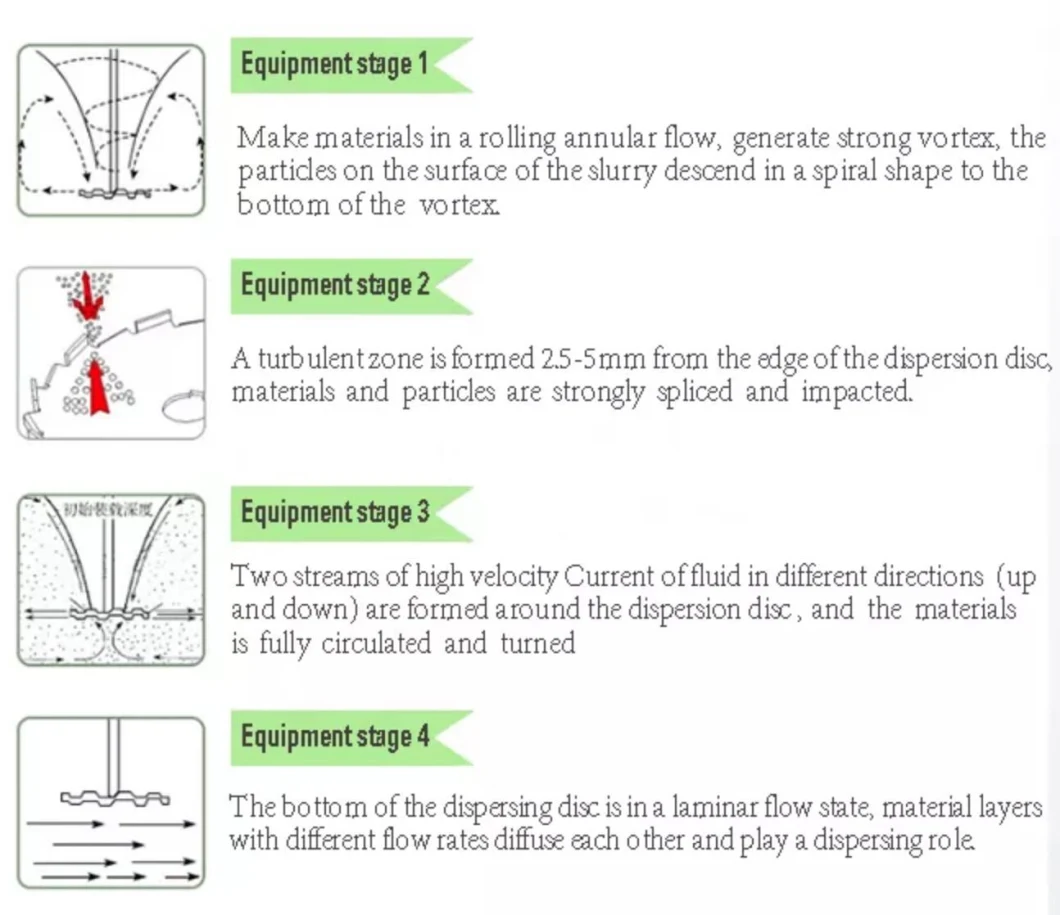

| Stirring Type | Spiral |

| Application | Liquid with Suspended Solids, Viscous Fluid, Liquid |

| Certification | CE, RoHS |

| Application Area | Daily Chemical |

| Layout Type | Verticle |

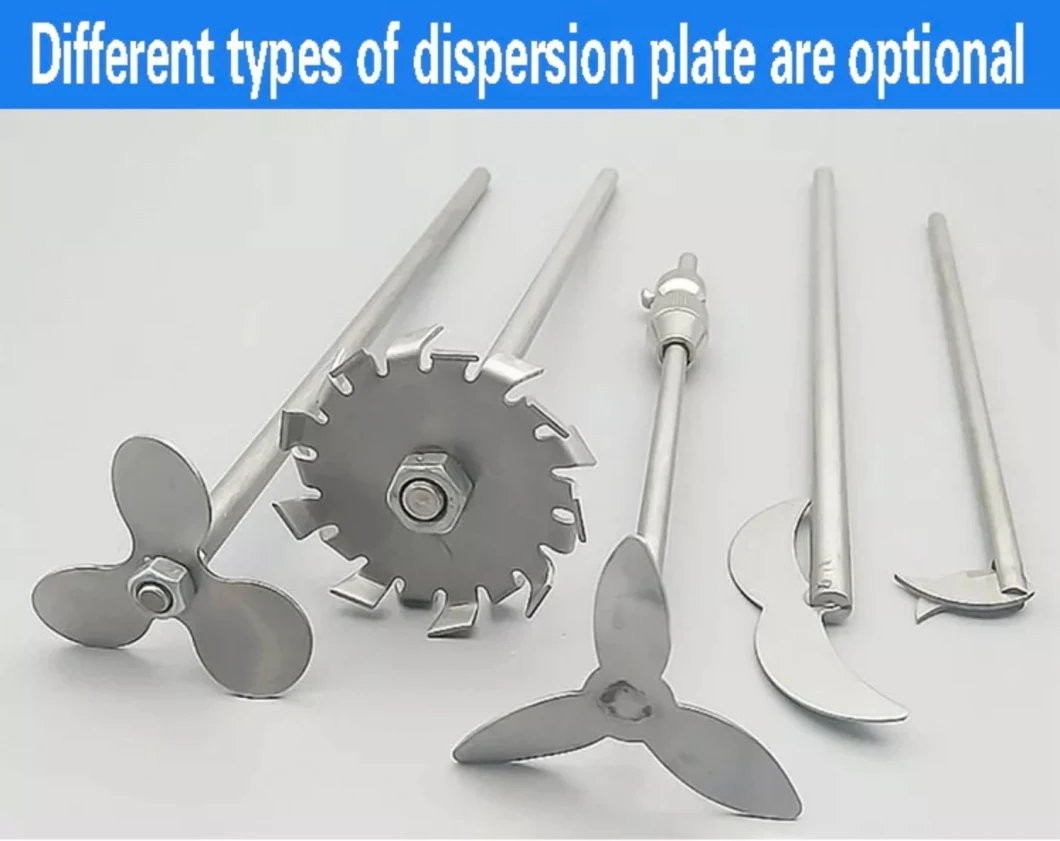

| Additional Capabilities | Milling |

| Operating type | Continuous Operating |

| Condition | New |

| Machine Material | SUS304&SUS316L |

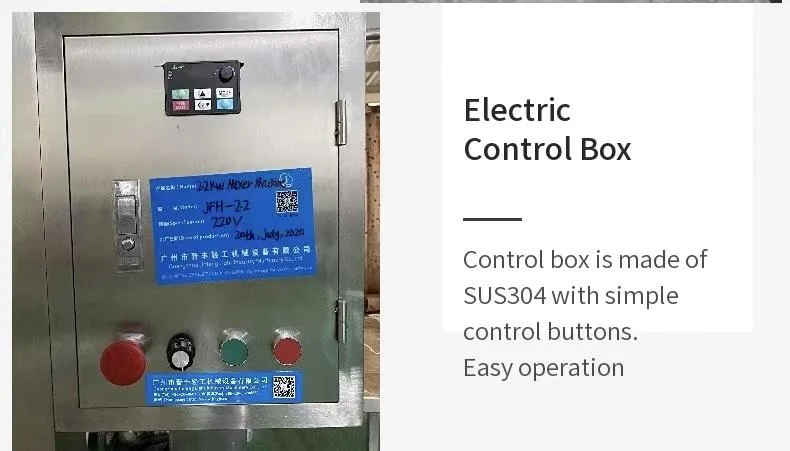

| Control | Button |

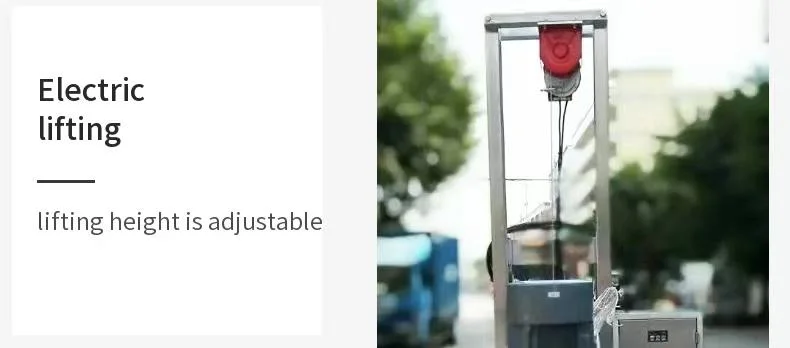

| Lifting Method | Pneumatic/Electric |

| Rotation Speed | 1440 r.p.m |

| Transport Package | Plywood Case Packing Suitable for Sea,Air Shipping |

| Specification | 1.5-7.5KW(customized is accepted) |

| Trademark | JINFENG |

| Origin | China |

| HS Code | 8474390000 |

| Production Capacity | 50-500L(Customized Is Accepted) |

Product Description

High quality stability disperser paint ink coating disperser manufacturer

Product Description

Characteristics

High quality SUS frame, high hardness, corrosion resistance, beautiful shape, stable and durable structure;

The contact part of the material is made of SUS304/316L, which is resistant to wear and corrosion and easy to clean;

High quality electrical components, variable frequency speed regulation, stable and safe work, long service life;

The lifting system is driven by electric power. It is equipped with lifting boom and sliding track of plane axis to make the lifting stable;

High quality SUS304 wire rope, durable, no burr, not easy to rust;Operation panel cleaning, simple and easy to operate, using frequency converter speed regulation, adjustable speed, stable performance, long service life.

Application industryIt is suitable for stirring, mixing and decomposition of materials in coating, paint, ink, medicine, papermaking and other industries. It is often used in laboratory and small batch production.

Product Parameters

| Model | Power(kw) | Lift height (mm) | Speed(r.p.m) | Stirring capacity (L) | Impeller diameter (mm) | Weight(kg) |

| JFD-1.5 | 1.5 | 600 | A:0-1500B:0-3000 | 10-50 | Φ100 | 250 |

| JFD-2.2 | 2.2 | 20-60 | Φ150 | 300 | ||

| JFD-3.0 | 3.0 | 800 | 20-100 | Φ200 | 330 | |

| JFD-4.0 | 4.0 | 380 | ||||

| JFD-5.5 | 5.5 | 1000 | 50-300 | 400 | ||

| JFD-7.5 | 7.5 | 450 |

Detailed Photos

Why Choose Us

Company Profile

We offering Turnkey service from A to Z to customers, we will can suggest customer the most suitable machines according to their Formula, Raw material. Support you Manufacturing- Installation- Training- Maintenance- Technical Support. We could also customize machines according to your demands, We could send our engineer to your factory to install machines and train your workers of operation and maintenance.

MATERIAL SOURCES OF PARTS80%of the main parts of our products are provided by world's famous suppliers. During long-term cooperation and exchange with them,we have accumulated much valuable experience, so that we can provide customers with high quality products and more effective guarantee.

FAQ

1. About Delivery termQ: What's the delivery term for doing business with you?

A: EXW/FOB/CIF/DDU… it depends on preference of clients. 2. About Lead timeQ: What's the leading time after placing order?

A: After getting your confirmation, mixing tank about 25 days, pump 15 days, colloid mill 10 days. However, it depends on production schedule is in slack or peak season, and the complication of machines. 3. About Payment timeQ: What's the payment term?

A: T/T 40% as down payment, 60% balance payment before delivery.4. About QualityQ: How do you control your quality?

A: All machines before delivery will be tested and send video for customer, if no problem then arrange balance payment. Meanwhile,CE is available for customers' needs.5. About PackingQ: How do you pack the machines?

A: Standard export wooden case, to avoid damage during delivery.6. About CustomizedQ: Can you produce according to the samples?

A: Yes,we can produce by your samples or technical drawings.