High Viscosity Rotary Conical Stainless Steel Food Powder Condiment Mixer

Basic Info

| Model NO. | TH-Y-0311 |

| After-sales Service | After Service |

| Warranty | 2years |

| Mixer Type | Homogenizer |

| Working | High Speed Mixer |

| Stirring Type | Spiral |

| Application | Liquid with Suspended Solids, Powder, Viscous Fluid, Liquid, Granules |

| Certification | CE |

| Application Area | Engineering & Construction |

| Layout Type | Horizontal |

| Mixing Drum Shape | Drum |

| Additional Capabilities | Milling |

| Operating type | Cycle Operating |

| Condition | New |

| Max. Loading Capacity | 150L |

| Material Processed | Plastics, Chemicals, Medicine |

| Power | 13 Kw |

| Keyword | 3D-Ribbor Mixer |

| Name | Powder Mixing Tank |

| Machine Type | Dispersion Blender Mixer Machine |

| Function | Mixer Blender |

| Usage | Mixing Paste Proucts |

| Application Scope | Chemical Cosmetic Food Pharmacy |

| Voltage | 220V/380V |

| Transport Package | Film and Woodencase |

| Specification | Stainless Steel 304/316 |

| Trademark | XINYU |

| Origin | Henan |

| HS Code | 8479820090 |

| Production Capacity | 300pieces a Month |

Product Description

| High viscosity rotary conical stainless steel food powder condiment mixer |

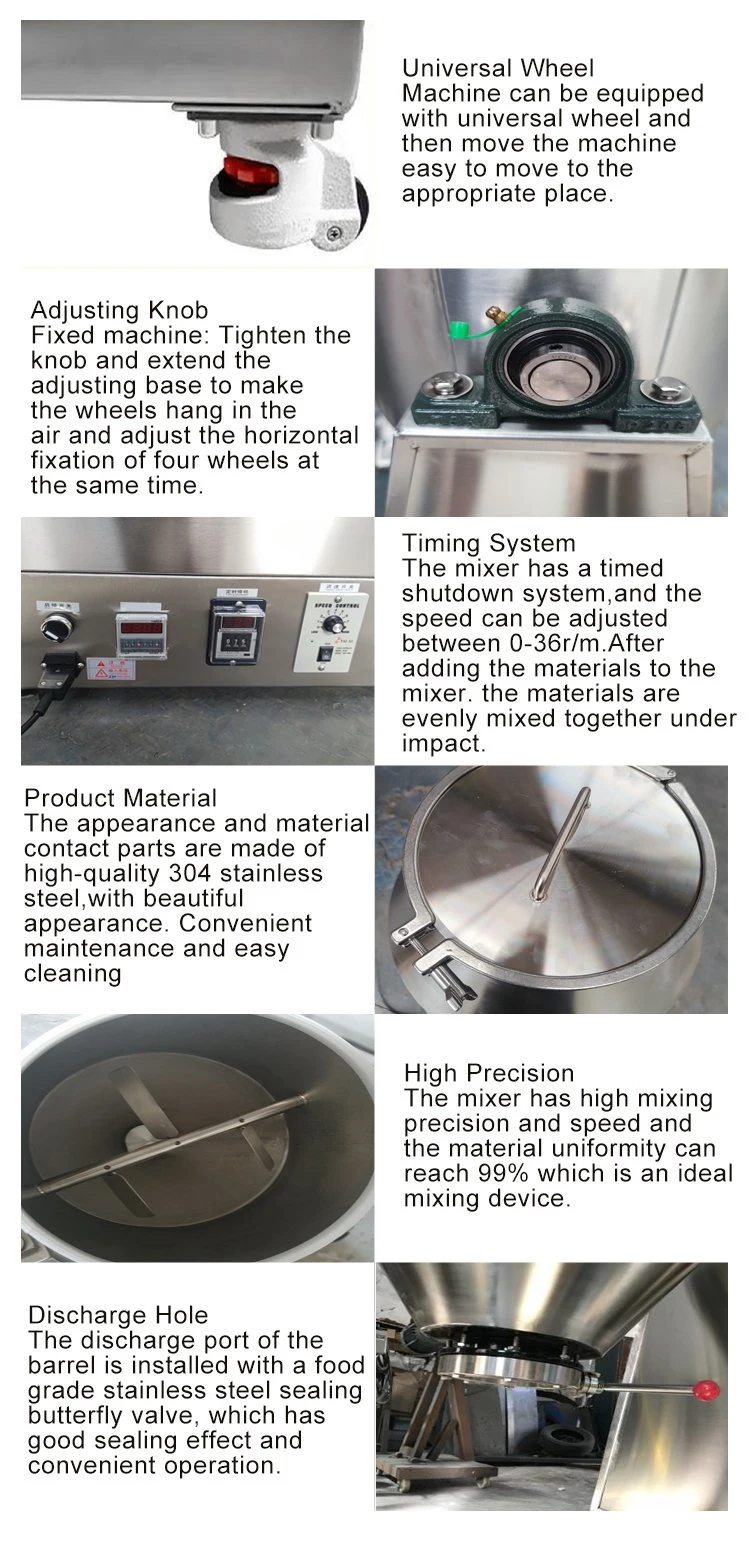

This drum mixer of our company is mainly composed of mixing drum, frame, transmission system, electrical system and other parts.It uses two asymmetric barrels and adopts gravity mixing. The materials are continuously gathered and dispersed in the barrel, generally after 10~ It takes about 30 minutes to mix, so that two or more powder and granular materials are fully mixed and uniform.This machine is mainly used for the uniform mixing of powder and granular materials in the pharmaceutical, chemical, electronic, and food industries.Product Parameters

| Product Model | TH-Y-0311 |

| Machine Material | Stainless steel 304 for all parts (Food Industry) |

| Voltage | 220v/380v |

| Power | 13kw |

| Machine Size | 450*320*580mm |

| Capacity | 0-150L |

| N.W. | 30KG |

1, Before Purchasing: We will provide professional technical project and sales consultation service to solve the customers' question;2, During Production: timely updates the machine status for customer to ensure delivery time, and quality guaranteed;3, After Production: Machine testing video and photos will be provided for inspection; 4, Before & During Shipment: The machine will be cleaned and packaged before delivery; All the documents will be provided for the seller;5, Installation & Training: Providing professional and expert technical engineers to supply the training and installation service.6, After Sales Service: engineers provide efficient service if the clients' need, such as formula, parameters setting, and spare parts;

FAQ1. Q: What's your MOQ? A: Generally, it's 1 sets for each machine. 2.

Q: Where is your factory located? What's the nearest air port and and how long it will take from airport to factory? A: Our factories are located in Henan province. The nearest airport is Xinzheng Internation Airport. 3.

Q: What's your lead time? A: It will be soon delivery if we have the exact specification machine in stock; For customized machine usually cost 3 - 10 days finished the machines. 4.

Q: What the payment terms required? A: T/T 50% and the balance paid before delivery For small order, West Union, PayPal or cash accepted. 5.

Q: Can products be customized? A: Customized products are welcome. And coming visit my company is welcome.