Category

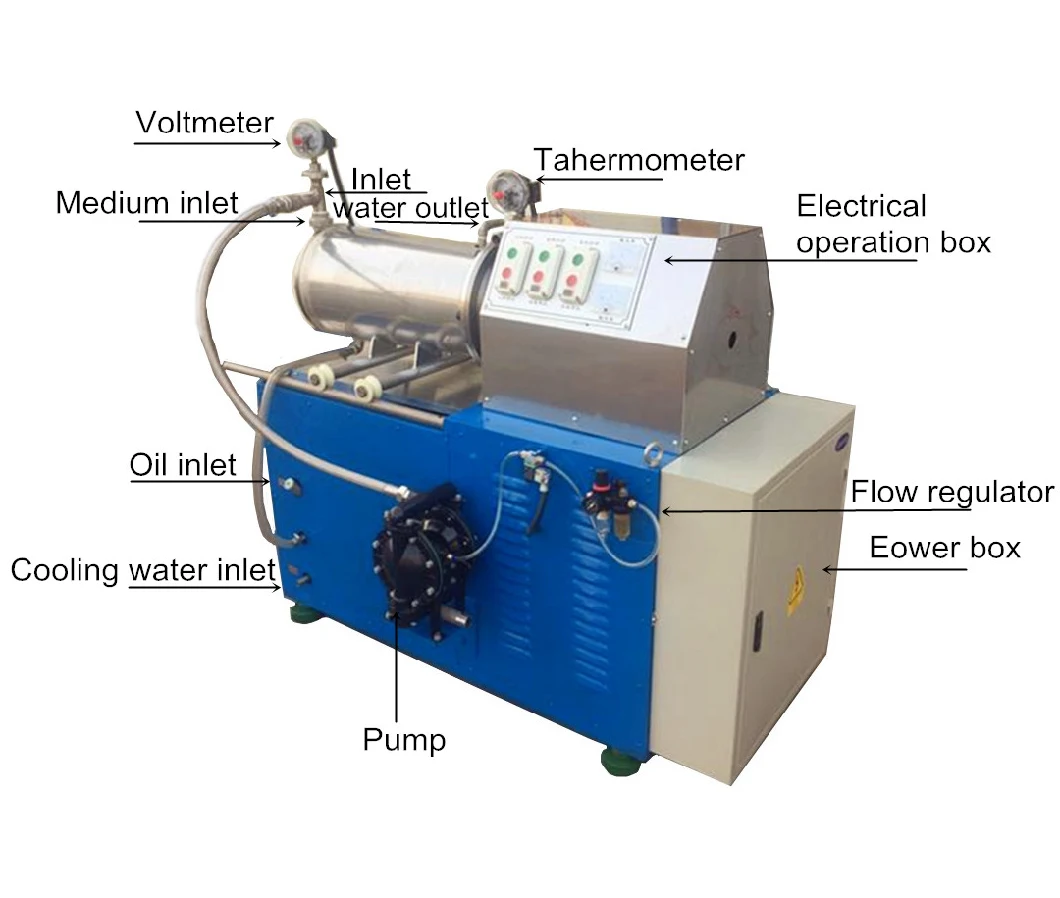

Horizontal Disc Type Pigment Grinding Sand Bead Mill Machine

Principle of Operation: The rotary grinding shaft drives all grinding mediums inside the grinding chamber. The grinding

Basic Info

| Model NO. | SW30L |

| Type | Disc Grinder |

| Power Source | Electricity |

| Object | Milling Cutter |

| Application | Chemical |

| Disc(Wheel) Type | Grinding Disc |

| Material | Aluminum Alloy |

| Working Style | High-speed universal |

| Disc Diameter | 180mm |

| Variable Speed | Without Variable Speed |

| Hscode | 8479820090 |

| Transportpackage | Plywood Packing |

| Transport Package | Plywood Packing |

| Specification | 30L |

| Trademark | keda |

| Origin | Shandong |

| HS Code | 8479820090 |

| Production Capacity | 1000PCS / Year |

Product Description

Principle of Operation: The rotary grinding shaft drives all grinding mediums inside the grinding chamber. The grinding mediums passes the powers to the materials to reduce the particle size. Gap separator inside the horizontal bead mills separates the products and the grinding mediums. They are suitable for different viscosities formulations.

Different materials inside the horizontal bead mills can be choosen, such as SS304, hard alloy, mold steel, polyurethane, tungsten carbide, ceramic etc.

Application:

| Agrochemicals | Pesticide, Herbicide, Fertilizer, SC |

| Ceramic Industry | Ceramic inks, Ceramic pigments |

| Printing Inks | Inkjet, Screen printing inks, Flexo printing inks |

| Pigments and Dyes | Pigment, Titanium dioxide |

| Paint and Coating | Construction Paint, Road Marking Paint, Wood Paint, Varnish, Marine Paint, Dispersion Paint, Automotive Paint, Coil Coating, Top Coat, Clear Coat |

| Minerals | Calcium carbonate, Pharmaceuticals, Cosmetics |

Disc bead mill is a type of horizontal bead mill with large flow capacity. As a type ultra-fine grinding mill, the disc beas mill is the most widly used, most advanced and most efficient grinding equipment. The disc bead mill can grind the material to be 2-20um, is widely used in mineral, coatings,dyes,inks,photosensitive material, pesticides, medicine, lithium batteries, nano new material, carbon nonatubes, cosmetics,graphene etc.

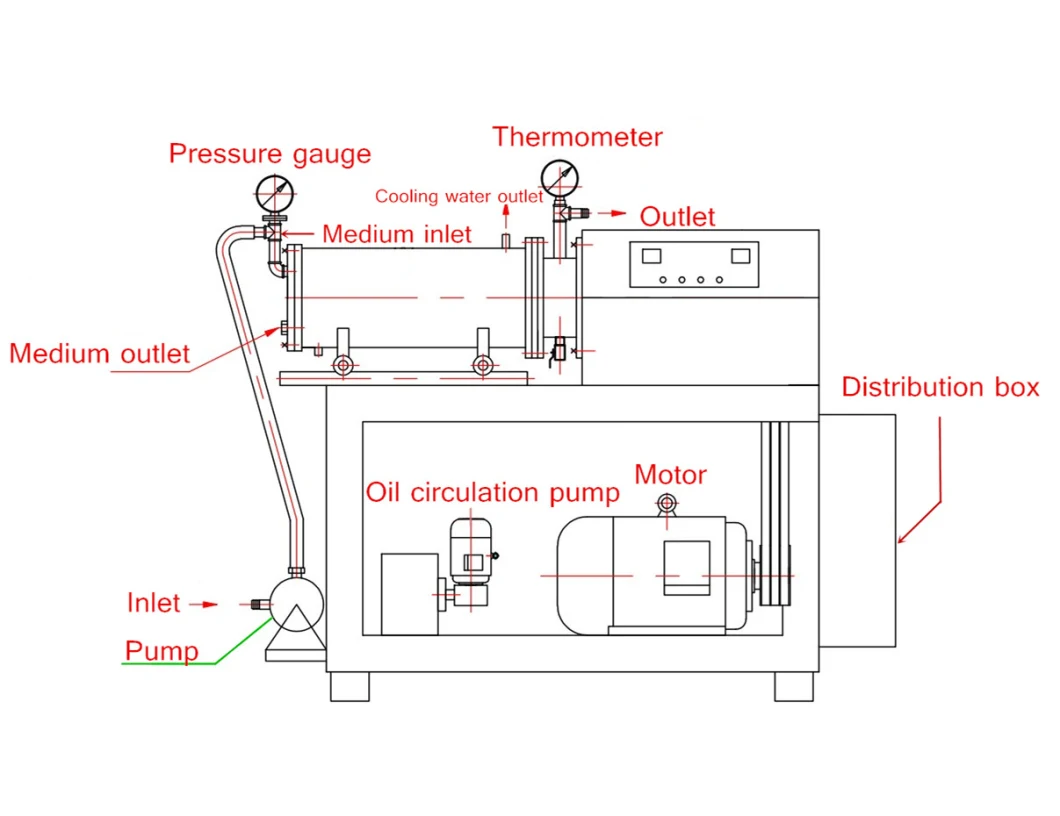

Working principle of disc bead mill

The dispersing device of disc bead mill is composed of a main shaft, a dispersing disc, a reflecting cage and a bushing. During operation, the mechanical energy generated by the rotation of the dispersing disc is transmitted to the grindingmedium through the rotation of the main shaft, so that the material is ground and dispersed uniformly. A reflective cage is arranged at the front end of the main shaft to prevent the grinding medium from collecting at the discharge scree and causing wear on the screen.

Features of disc bead mill

1.Elimination of all radial openings in the mill chamber.

2.Allowing for installation of exchangeable, through-hardened liner.

3.Exchangeable,through-haedened front & end plates and hardened wear bushing at exposed loacations.

4.Combination of neutral and conveying high intensity agitator discs,specific design featuring increased diameter.

5.Bead retention by centrifugal implement screen.