Industrial Grade Ultrasonic Disperser for Ink Extraction Processor

Basic Info

| Model NO. | RPS-SONO20 |

| Application Area | Agricultural Chemicals |

| Layout Type | Verticle |

| Operating type | Continuous Operating |

| Condition | New |

| Horn | Titanium Alloy |

| Generator | Dg Generator |

| Voltage | 220/110V |

| Temperature | 300 |

| Power | 3000 |

| Capacity | 20 L/Min |

| Pressure | 35 MPa |

| Volumn | Customized |

| Advantages | High Speed and Efficient |

| Transport Package | Carton |

| Specification | 45*22*27 |

| Trademark | RPS-SONIC |

| Origin | China |

| HS Code | 8515900090 |

| Production Capacity | 200 |

Product Description

Basic Info.

| Model NO. | RPS-SONO20 |

| Condition | New |

| Frequency | 20kHz |

| Generator | Dg Generator |

| Horn | Titanium Alloy |

| Capacity | 20 L/Min |

| Transport Package | Carton |

| Trademark | Rps-sonic |

| Origin | China |

| HS Code | 8515900090 |

| Production Capacity | 200PCS/Month |

| Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

| Power | 1000 W | 2000 W | 3000 W | 3000 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ºC | 300 ºC | 300 ºC | 300 ºC |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Intensity of sound | 20 W/cm² | 40 W/cm² | 60 W/cm² | 60 W/cm² |

| Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Introduction:

As the main transportation means at sea, ships have played a huge role in international trade. However, if the microorganisms in the ship's ballast water are discharged locally without treatment, they will pollute the local ecological environment and seriously damage biodiversity and even endanger human health. There are more than 20 kinds, but none of these methods can meet the five standards of safety, practicality, economy, efficiency and environmental tolerance proposed by IMO. The ultrasonic cavitation effect can kill all kinds of marine life and protect the ocean. Safety and life of the facility.

Ultrasonic Ballast Water Treatment

Marine fouling organisms can be divided into the following three categories

- Soft growths such as sponges;

- Bacteria and single-cell organic matter, such as various types of bacteria and algae;

- Hard marine animals, such as barnacles, bivalve molluscs, etc.

The most harmful species are mainly hard-fouling organisms

- Will damage the surface of the metal structure, which will cause local corrosion;

- Larger fouling organisms can block water supply and drainage pipes, heat exchangers, etc., which seriously affects the safety of marine facilities and their service life.

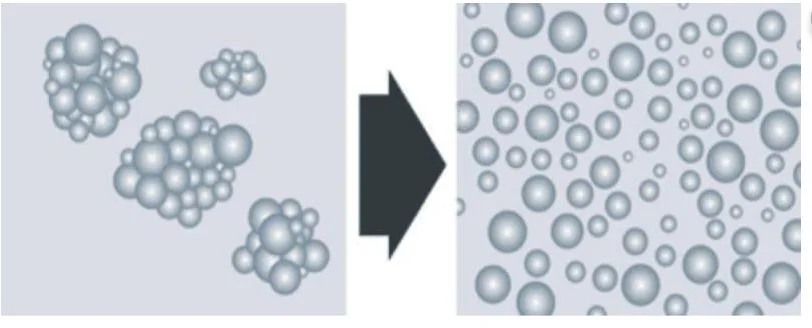

The air bubbles in the liquid produce more than a few hundred atmospheres and a high temperature of thousands of degrees Celsius at the moment of rupture, which can make the sea creatures' attachments quickly peel off and break the epidermal cells of the sea creatures, thereby achieving the purpose of preventing sea creatures. The ultrasonic cavitation technology has its advantages. It not only has simple device design and convenient operation, but also does not generate secondary pollution. The most important thing is that the ultrasonic wave and hydrodynamic cavitation have better synergistic treatment effect, and the energy consumption is not high.

Ultrasonic sea defense biological technology has been applied in practice and achieved good results. The technology has the advantages of simplicity, economy, effectiveness, and environmental protection. It can not only remove the sea creatures attachment on the inner wall of the seawater pipeline and the filter screen, but also kill the sea creatures' larvae.

The technology of ultrasonic degradation of organic pollutants in sewage can be used alone, or the ultrasonic cavitation effect can be used to combine ultrasonic degradation technology with other treatment technologies to degrade and remove organic pollutants. There are the following types of combined technologies:1. Ultrasonic combined with ozone for sewage treatment, combined with ultrasonic degradation, sterilization and ozone disinfection for sewage treatment.2. The combined use of ultrasonic and hydrogen peroxide for sewage treatment to achieve the purpose of degradation, sterilization and disinfection of polluted water bodies.3. Ultrasonic combined with ultraviolet rays for wastewater treatment. The photoacoustic chemistry technology uses ultrasonic and ultraviolet light technologies to degrade the synergistic and complementary effects of their respective degrading abilities. It is effective against common organic pollutants such as phenol, tetrahydrocarbon, trihydromethane and Trichloroacetic acid is degraded so that the degradation products of the four substances are water, carbon dioxide, C1- or short-chain fatty acids that are easily biodegradable.4. Ultrasonic combined with magnetization treatment technology for sewage treatment. Magnetization can not only achieve solid-liquid separation of sewage, but also degrade organic substances such as COD and BOD. It can also decolorize dyeing water.5. Ultrasonic can also be used as an auxiliary technology for traditional chemical sterilization treatment. When large-scale sewage treatment is performed by traditional chemical methods, increasing ultrasonic radiation can greatly reduce the amount of chemical agents.