Category

Liquid Mixing Tank with Agitator Tank Jacketed Mixing Vessel

liquid soap mixing equipment is designed for making cosmetic cream lotion gel and liquids washing Shampoo etc Product De

Basic Info

| Model NO. | Liquid Mixing Tank with Agitator Tank Jacketed Mix |

| Certification | CE, ISO, GOST, SONCAP, CCC, API |

| Application Area | Daily Chemical |

| Layout Type | Verticle |

| Mixing Drum Shape | Conical |

| Additional Capabilities | Milling, Granulating, Coating |

| Operating type | Continuous Operating |

| Condition | New |

| Mixing Homogenizer Mixer Conditioner, L | Mixing Homogenizer Mixer Conditioner, Liquid Dete |

| Liquid Soap Making Machine Cosmetic Mixi | Liquid Soap Making Machine Cosmetic Mixing Machine |

| Liquid Soap Making Machine Washing Powde | Liquid Soap Making Machine Washing Powder Manufact |

| Hand Wash Liquid Soap Detergent Making M | Hand Wash Liquid Soap Detergent Making Mixer Machi |

| Liquid Soap Shampoo Lotion Detergent San | Liquid Soap Shampoo Lotion Detergent Sanitizer Mix |

| Liquid Soap Shampoo Liquid Hand Wash Mak | Shampoo Liquid Hand Wash Making Machine |

| Liquid Soap Shampoo Liquid Hand Wash Ma | Liquid Soap Shampoo Liquid Hand Wash Making Machi |

| Automatic Paint Toothpaste Dispenser Liq | Automatic Paint Toothpaste Dispenser Liquid Soap M |

| CE Proved Homogenizer Mixing Machine Liq | CE Proved Homogenizer Mixing Machine Liquid Soap S |

| Foaming Laundry Detergents Shampoo Soap | Foaming Laundry Detergents Shampoo Soap Liquids So |

| Mixing Tank Paint Mixing Machine Liquid | Mixing Tank Paint Mixing Machine Liquid Soap Makin |

| Stainless Steel Mixing Tank Liquid Soap | Stainless Steel Mixing Tank Liquid Soap Making Hom |

| Shampoo Liquid Detergent Liquid Soap Hom | Shampoo Liquid Detergent Liquid Soap Homogenizing |

| Shampoo Mixer Equipment/Liquid Soap Maki | Shampoo Mixer Equipment/Liquid Soap Making Machine |

| Antibacterial Hand Sanitizer Gel Homogen | Antibacterial Hand Sanitizer Gel Homogenizer Mixer |

| Transport Package | Wooden Case |

| Specification | set |

| Trademark | Shuangyu |

| Origin | China |

| HS Code | 8479820090 |

| Production Capacity | 1000 Per Year |

Product Description

liquid soap mixing equipment is designed for making cosmetic cream lotion gel and liquids washing Shampoo etc

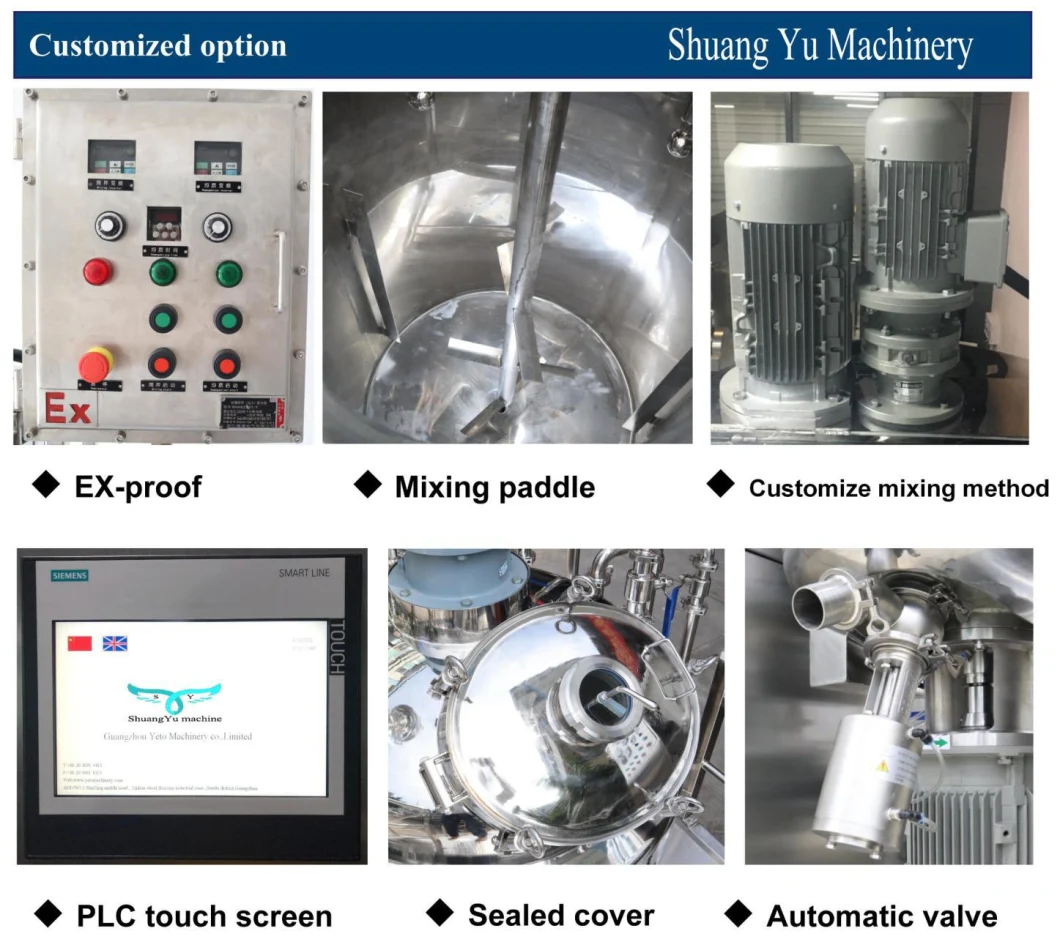

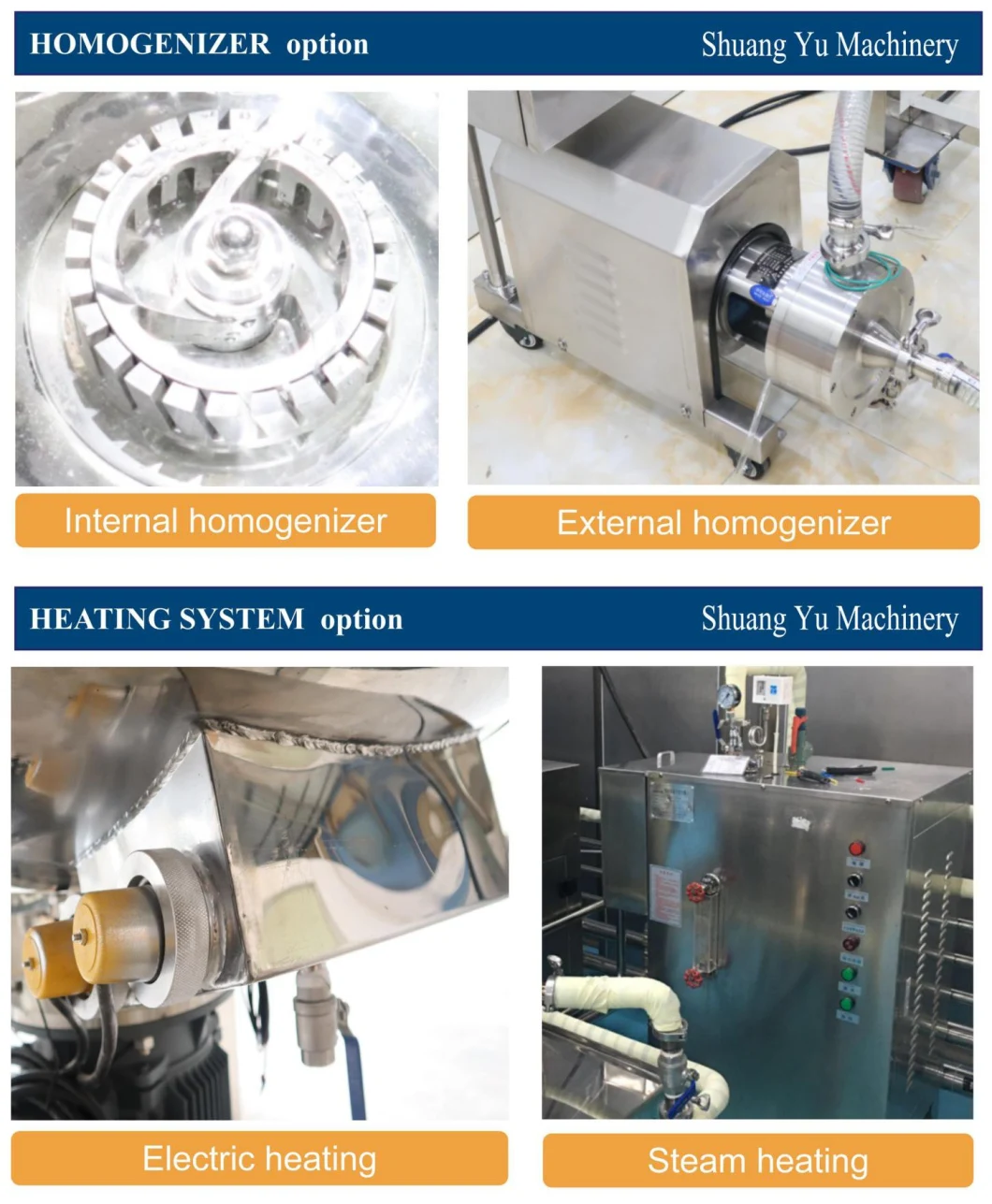

This series liquid soap mixing equipment is designed for making cosmetic cream lotion gel and liquids washing products, we adopt pharmaceutical grade stainless steel , with electric heating, high shear homogenizer emulsifier mixer, wall scraper agitator blender, three layers stainless steel working pot, mixing paddle, control cabinet . Each function can be controlled separately . working capacity 50L-200000L can be customized according to customer's requirements. Which used for making cosmetic cream paste lotion gel, liquids soap detergent, dishwashing detergent soap, facial cleanser, emulsion products, chemical industrial cleaning products and personal care products , etc .

| Capacity: | 100-5000L(can be customerized) |

| Mixing Power: | 0.75-15KW |

| Mixing Speed: | 0-60 (R/MIN) |

| Homogenizing power: | 2.2-22 KW |

| Homogenizing speed: | 3000 (R/MIN) |

| Heating Mode: | Steam heating or electric heating (optional) |

Usage:

Detergent body wash shower gel shower cream liquid soap shampoo mixing making machine,Automatic Electric Heating Detergent Mixing Machine,Shampoo Blending Tank is mainly suitable for preparation of liquid detergents(such as cleanser essence,shampoo and shower cream etc)

Integrating blending ,dispersing ,heating and cooling etc. functions,the reacting machine is an ideal device for liquid perparation in various factories .

1.Warranty time: one year, from the date which the product is qualified commissioning. Any damage except the wrong operation during warranty period is repaired freely.But the travel and hotel expenses should be count on buyer.2. Commissioning services: the product's installation and commissioning at the demand side, our engineers will not leave there until get your agreement.3. Training services: our engineers will train your staff to operate it during the period of installation and commissioning,and they will not leave there until your staff can operate it properly and normally.4. Maintenance services: any malfunction happened, once you inquiry us, we will reply you within 48 hours except the special reasons.5. Lifelong services: we provide lifelong services for all the products we sold out, and supply the spare parts with discount price.6. Certificate services: we can provide related certificates to customers freely according to the request of customers.7. Inspection services: you can ask the third part inspection company or your inspector to inspect the products before shipment.8. The file: the Manual Specification, report of the material which used to the equipment and other documents related to the GMP authentication information will be provided by us.

RFQ

Q: Are you a factory?

A: Yes we are a factory with more than 20 years manufacturing experience. One is in Jjiangsu Province,Another is in Guangzhou next to our office.

Q:I'm new in our industry,but I'm planing to set up a factory, what canI do?

A: We will design the most suitable proposal based on your actual situation, such as the daily production,raw material formula, factory layout, etc. Also we would like to intro- duce some excellent suppliers of raw materials, bottles,labels, etc if needed. After sales, engineer will be send to fields installation, training and commissioning.

Q: How can you control the quality before delivery?

A: First, our component/spare parts providers test their products before they offer com- ponents to us.Besides, our quality control team will test machines performance or running speed before shipment. We would like to invite you come to our factory to verify machines yourself. If your schedule is busy, we wil take a video to record the testing procedure and send the video to you.

Q:Are your machines difficult to operate? How do you teach us using the machine?

A: Our machines are fool-style operation design,very easy to operate.Besides,before delivery we will shoot instruction video to introduce machines'functions and to teach you how to use them.If needed engineers are available to come to your factory to help install machines, test machines and teach your staff to use the machines.

Q: Can I come to your factory to observe machine running?

A: Yes, customers are warmly welcome to visit our factory.

Q: Can you make the machine according to buyer's request?

A: Yes,OEM is acceptable. Most of our machines are customized design based on cus- tomer's requirements or situation