Category

Pin Mill for Corn Wet Milling Plant Corn Starch Processing Equipment Maize Starch Machinery Suppliers Corn Starch Factory Machine

Pin Mill for Corn Wet Milling Plant Corn Starch Processing Equipment Maize Starch Machinery Suppliers Corn Starch Factor

Basic Info

| Model NO. | Myande |

| Installation Time | 2 Months |

| Warranty Period | One Year |

| More Information | Design by Customer′s Requirments |

| Transport Package | Container |

| Specification | ISO |

| Trademark | Myande |

| Origin | Yangzhou, Jiangsu |

| Production Capacity | 200units/Year |

Product Description

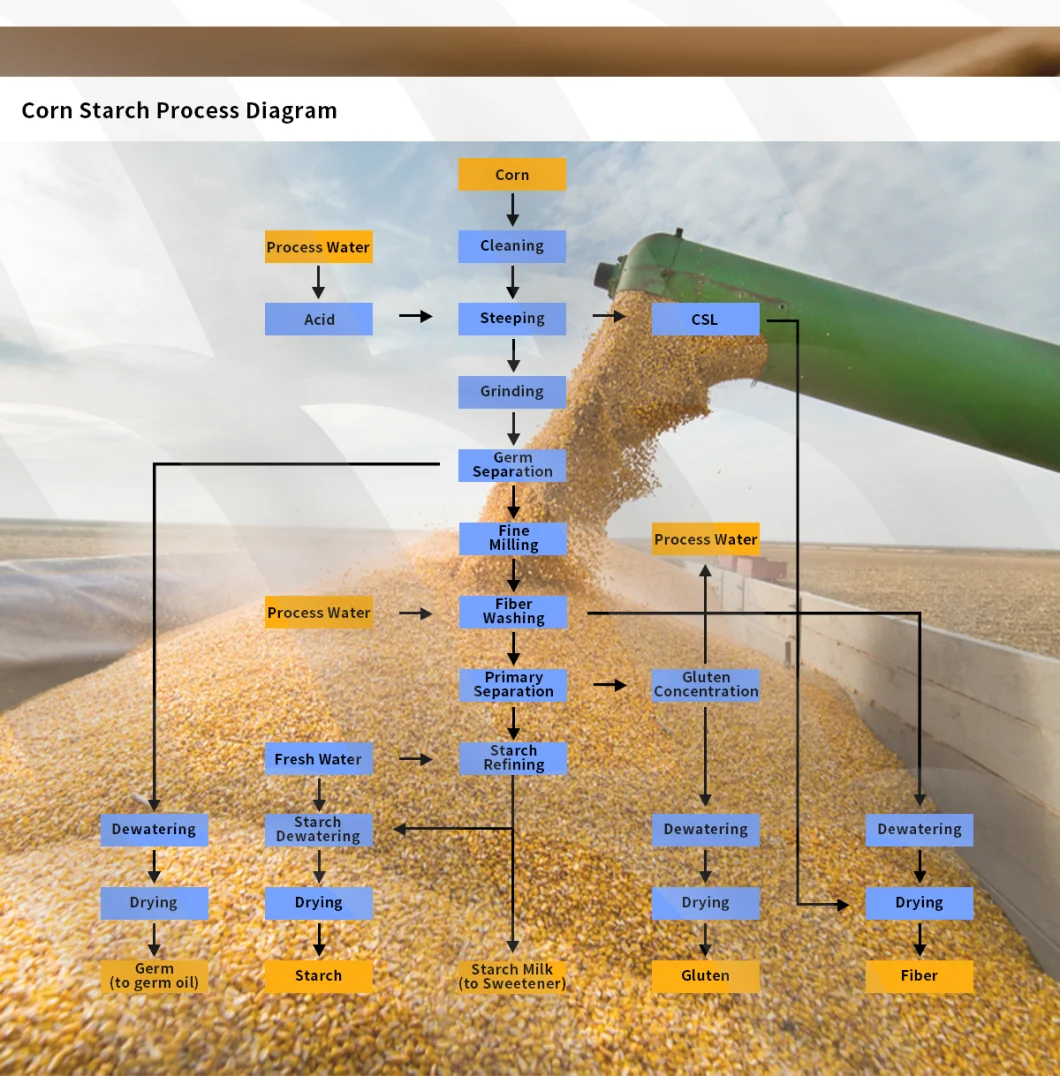

Pin Mill for Corn Wet Milling Plant Corn Starch Processing Equipment Maize Starch Machinery Suppliers Corn Starch Factory MachineCorn starch can be consumed directly as human food as well as an important raw material for producing starch sugar. It is widely used in pharmaceutical, textile, fermentation, chemical and other industries.Myande corn starch processing technology adopts "steeping-grinding-separation" wet milling process. Its technical features include energy efficiency and low steam and water consumption, with fresh water being consumed only at the starch milk washing section, while all other sections make use of process water in a closed-loop circulation. The closed-loop process not only reduces water consumption but increases total dry matter recovery rate. The environmental-friendly feature effectively minimizes effluent and energy consumption.We provide turnkey corn starch plant for you with capacity ranging from 100TPD to 4,000TPD.

You might also be interested in other industry solutions:

Corn Starch/ Wheat Starch/ Wheat GlutenPotato StarchSweet Potato StarchCassava StarchPea Starch And ProteinRice Starch And ProteinModified StarchGlucose Syrup/ MaltoseDextrose MonohydrateDextrose AnhydrousFructose SyrupMaltodextrinLysineBioethanolSorbitolCitric AcidDDGS

What can we do for you?

We focus on supplying one-stop engineering service covering general layout plan, process design, R&D, equipment manufacturing, automatic control system, data integration, installation, supervision, commissioning, training and etc.Our custom solutions come from a deep understanding of your needs, and we have the capability to complete each project from the design of the initial concept to manufacturing, installation, commissioning and delivery.

Solution Tailored to Your NeedsGeneral layout planWith a land prepared, the next thing you should consider is planning the general layout, which is a crucial foundation of a sustainable and cost-effective manufacturing.Turn to us for help and we will present you the design for your plant by considering water, steam, electricity supply and etc.Process designCombining our engineering expertise, industry know-how and practical skills with your knowledge, we provide the optimized and customized process design for your plant.3D plant designOn the basis of plant layout design, combined with real situation, we can design a three-dimensional model of the entire plant. All the equipment, piping and instruments, any detail can be shown in the model, not only allowing you to have an intuitive understanding of the plant, but also providing overall information support for plant construction, equipment installation and future expansion.Automatic control systemWe offer economical and most effective process automation solutions for the entire production line. Our RES automatic control system is developed based on PLC/DCS system.Data integrationFrom the perspective of the overall operation of the factory, Myande intelligent data integration management system collects basic data from raw grain procurement, warehousing, processing, inventory, sales and logistics, relying on the interconnection network system of each workshop. It provides real-time, accurate and traceable data reports for the current storage, processing and shipping.Equipment manufacturingWe owns in-house manufacture base of more than 120,000 SQM integrating R&D, production, project management which represents advanced engineering capability in the industry.Installation and commissioningAfter finishing the installation of all machines, we offer on-site commissioning service to ensure compatible functioning.Every move of the machine needs strong technical support from our experienced engineers. The only principle is that you can start manufacturing right after the commissioning.

No Compromise on Quality

At Myande, we are committed to providing high-performance equipment. We achieve this by applying strict quality management with the active engagement of all engineers and workers.Based on this system and our high-standard manufacture base, we can guarantee quality consistency by employing innovative technology and precision craftsmanship. Hence, we build our reputation as a consistent and reliable supplier.

Certificates & Patents

Our Global Presence