Turbo Turbine Horizontal Bead Mill for Ultrafine Grinding Water Based Printing Ink

Basic Info

| Application 1 | Water Paints |

| Application 2 | Solvent Paints |

| Application 3 | Printing Ink |

| Application 4 | Water Soluble Fertilizer |

| Application 5 | Pesticide Suspending Agent |

| Application 6 | Sulphur Suspended Agent |

| Application 7 | Graphene |

| Application 8 | Color Paste |

| Application 9 | Dyes |

| Application 10 | Car Paints |

| Transport Package | Wooden Case Package |

| Specification | 50 |

| Origin | China |

| HS Code | 8479820090 |

| Production Capacity | 15 Sets Per Month |

Product Description

Model:PSM-T seriesPSM-T series turbo sand mill adopts a multi-channel turbo dispersion structure, and uses the centrifugal force generated by the turbo rotor to discharge the materials from the turbo grinding chamber.This design can convert the axially moving media in the grinding chamber into several "particle streams" perpendicular to the circumferential direction of the shaft, greatly increasing their shearing capacity. In addition, the whole grinding process has a short time and large energy, which avoids the rapid heating of the material.It is the best choice for grinding medium and low viscosity materials. It is especially suitable for medium and low viscosity materials (<10000cps) such as liquid ink, digital inkjet, carbon black, industrial paint, automotive paint, latex paint, titanium dioxide, etc.

Product Features

It has the following characteristics:

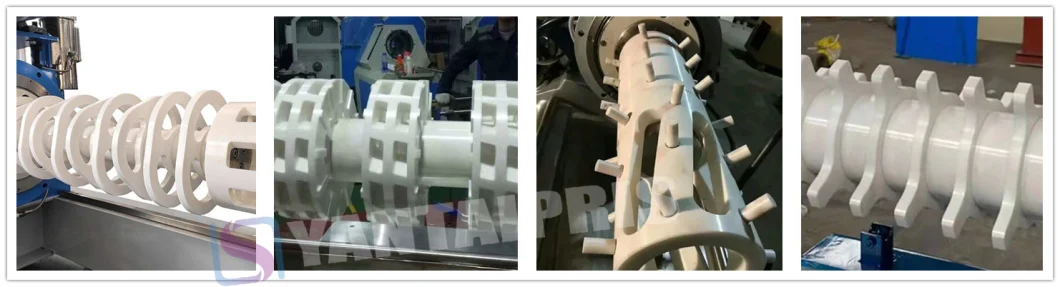

1. Contacting parts material can be customized: The grinding chamber and turbine can be customized as polyurethane, zirconia or other composite materials to achieve production without metal pollution;

2. The special-shaped turbine designed by scientific calculation and many experiments, the radial pressure difference generated during high-speed rotation will form a strong vortex force (maximum linear speed 14-15m/s), making the grinding medium High speed can be obtained without contacting the turbine, which improves the grinding efficiency and avoids the large amount of thermal energy generated by the strong impact in the ordinary grinding form. At the same time, the cycle of replacing turbine wearing parts is extended;

3. The slot-type dynamic separator has self-cleaning ability, is not easy to be blocked, and has a long service life;

4. The diameter of grinding media can be selected from 0.3 - 1.2mm;

5. The discharge reaches the ultra-high fineness of sub-micron level (100nm~1.0μm).

6. Scope of application: material viscosity <10000cps.