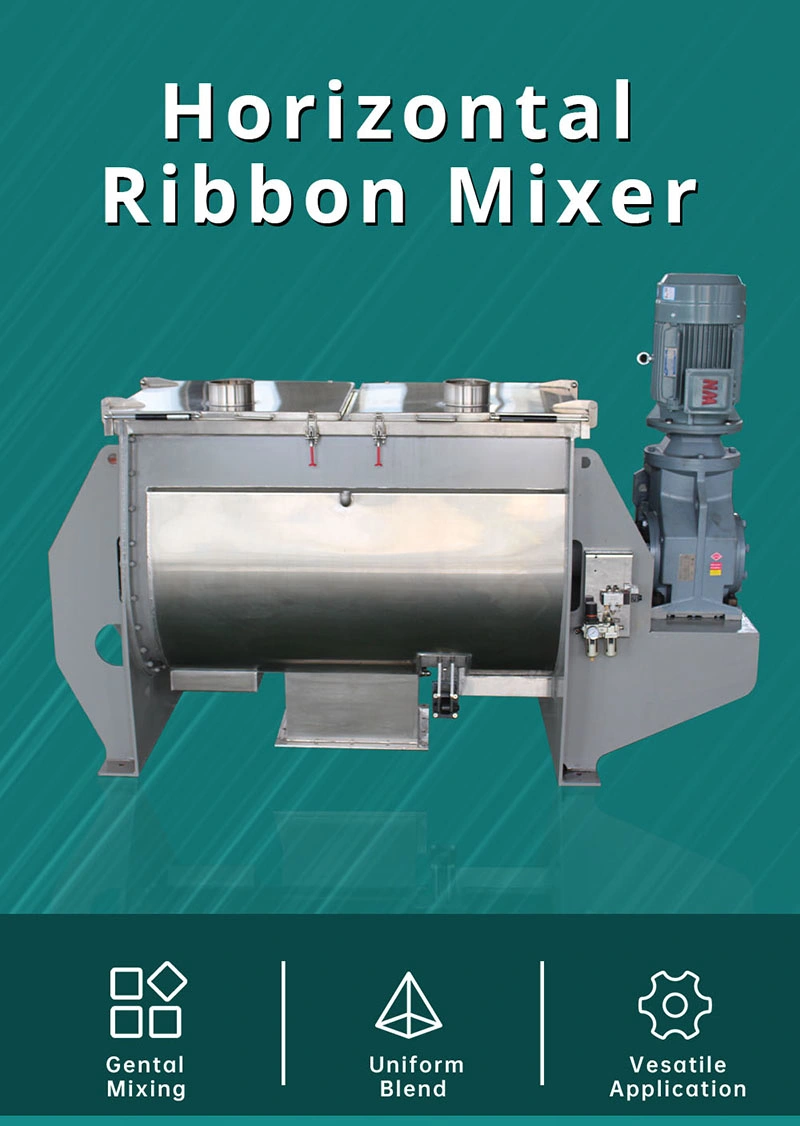

Industrial Chemical Food Dry Powder Horizontal Batch Double Spiral Ribbon Paddle Plough Blender Mixing Mixer in Competitive Price

Basic Info

| Model NO. | WLH |

| Certification | CE, ISO |

| Application Area | Daily Chemical |

| Layout Type | Horizontal |

| Mixing Drum Shape | Circular Groove |

| Additional Capabilities | Drying, Coating |

| Operating type | Cycle Operating |

| Condition | New |

| Operation | Batch |

| Explosion-Proof | Optional |

| Electricity | 50/60Hz |

| Wearable Parts | Loose Supply |

| Lead Time | 30 Working Days |

| Video Inspection | Support |

| Customerized Design | Support |

| Installation Support | Upon Request |

| Local Commissioning | as Request |

| Type | Industrial Powder Mixer Blender Mixing Machine |

| Transport Package | Plywood Case Packing |

| Specification | 300L -10000L |

| Trademark | Wiscon |

| Origin | China |

| HS Code | 8474390000 |

| Production Capacity | 600 Units/ Year |

Product Description

Product Description

The ribbon blender is versatile blending equipment with high efficiency, uniformity, and low crushing. Its double ribbon agitatorcan make the materials well mixed in a short time, ribbon blender shows a wide application for mixing dry powders, granules,and viscous pastes homogeneously.

Applicable Materials

Mixing of dry, paste, and Solid-Liquid Suspensions

Typical Application

Bakery premixes cosmetics, instant drink nutraceuticals, protein powders, spices, sugar mixture, vitamins, animal feed, ceramics,pigments, catalysts, Plastic resins, carbon black, polyethylene, polymer additives, PVC compounding, cleaning compounds,talcum powders, laundry detergents

Working Principle

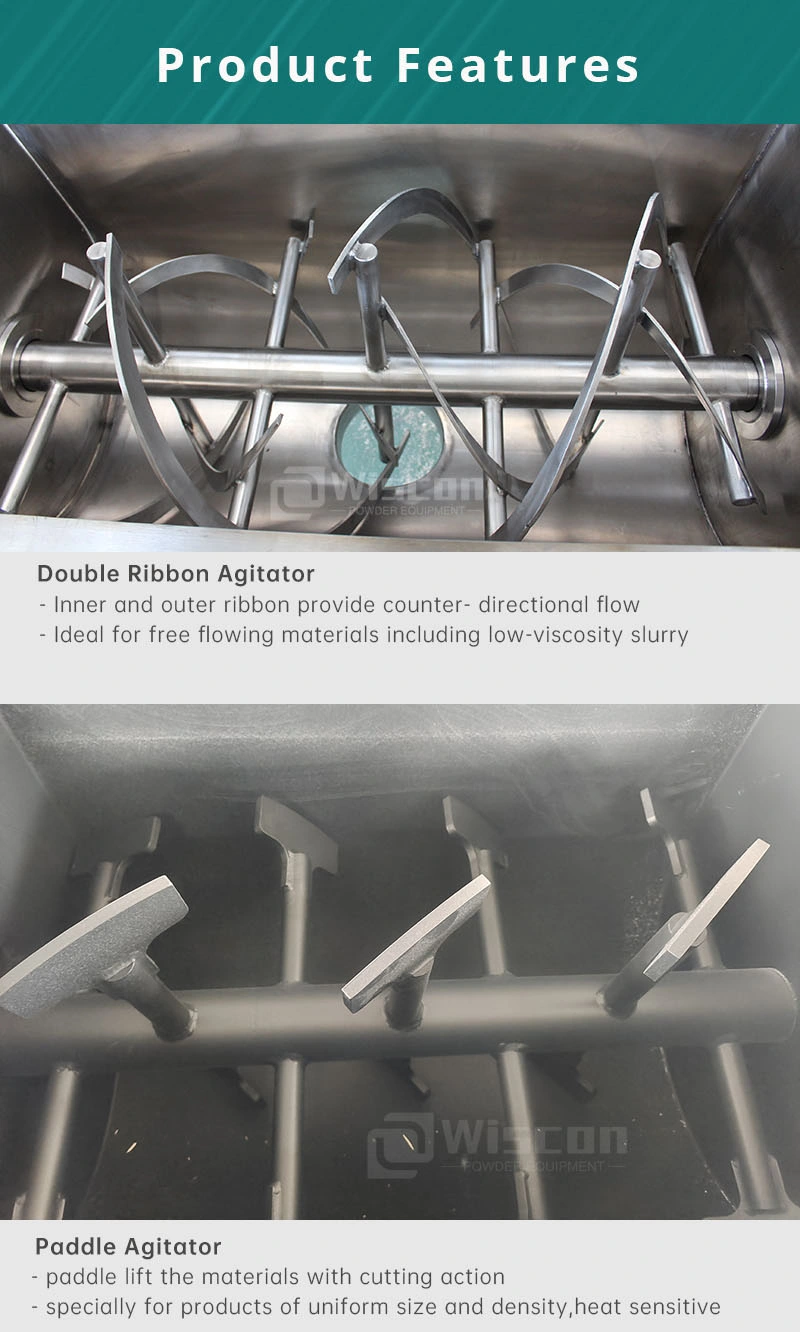

The horizontal ribbon blender consists of a U-shape trough with a semicircular bottom and is fitted with a horizontal longitudinal shaft.The shaft has mounted arms supporting a double spiral type ribbon. inner ribbons move materials toward the ends of the ribbonblender whereas the outside ribbons move material back toward the center of the ribbon blender. The ribbons move materials bothradially and laterally to insure thorough blends in short cycle times. the materials form the axial reciprocating motion in the mixingchamber. Material outlets are in the middle of the cylinder bottom. The outside ribbon driven by the main shaft moves materialsto discharge.

| Model | Total Volume(L) | Max Loading (kg) | Power (kw) | Speed (r/min) | Overall Size (mm) |

| WLH-0.3 | 300 | 180 | 4 | 63 | 1800×860×1000 |

| WLH-0.5 | 500 | 300 | 5.5 | 63 | 2000×1100×1200 |

| WLH-1 | 1000 | 600 | 7.5 | 41 | 2400×1400×1380 |

| WLH-1.5 | 1500 | 900 | 11 | 41 | 2610×1560×1570 |

| WLH-2 | 2000 | 1200 | 15 | 32 | 3000×1600×1630 |

| WLH-3 | 3000 | 1800 | 18.5 | 32 | 3300×1700×1800 |

| WLH-4 | 4000 | 2400 | 22 | 29 | 3170×1850×1900 |

| WLH-5 | 5000 | 3000 | 30 | 29 | 3900×2000×2200 |

| WLH-6 | 6000 | 3600 | 37 | 26 | 4200×2100×2100 |

| WLH-8 | 8000 | 4800 | 45 | 26 | 4600×2200×2300 |

| WLH-10 | 10000 | 6000 | 55 | 23 | 4900×2400×2400 |

Wuxi Wiscon mechanical and Electrical Equipment is an integrated company specializing in powder production for the food,pharmaceutical, chemical, and biological industries since 2016.

Main products categories cover the following equipment:

a. Drying Equipment: rotary atomizer spray dryer, pressure nozzle spray dryer, tray drying oven.

b. Powder Mixer: Conical Screw mixer, Ribbon mixer, Ploughshare Mixer, V-shaped mixer, and Double cone mixer for bulk materials.

c. Vibration Screener: Rotary vibratory Screener, Tumbler Screening Machine, and Centrifugal shifter for fine powder separation.

d. Grinding Machine: Universal Mill, Air Classified Mill for food and Pharmaceutical.

e. Granulating Equipment: High Shear Mixer Granulator and Fluid Bed Granulator

f. Vacuum conveyor: Pneumatic vacuum Feeder for BIC, Bagging machine, powder mixer, sieve, etc.

Questionnaire for ribbon paddle mixer

In order to quote you the right ribbon paddle mixer price, Please specify as much information as possible

- What are the materials to be handled?

- What's the mixing capacity per batch?

- What is the particle size of the raw materials?

- What is the bulk density of raw materials?

- Does the product need to be heated or cooled while mixing?

- Does the mixer need to have a vacuum applied when the product is mixing?