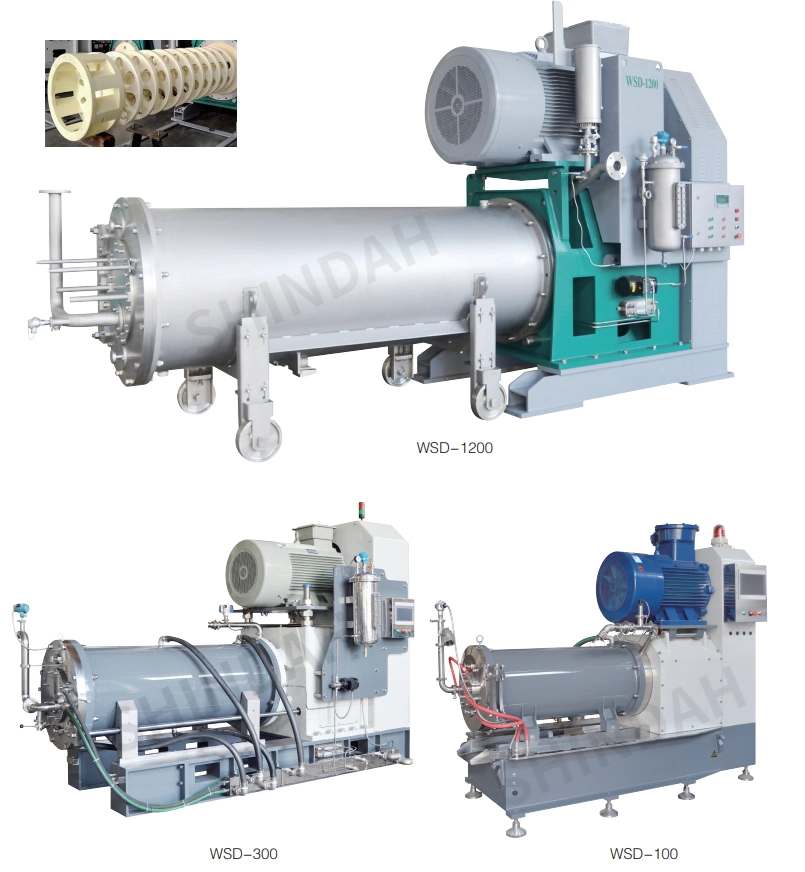

Bead Mill Sand Mill Large Flow Rate Disc Mill for Dry Industry

Basic Info

| Model NO. | WSD1200 |

| Working Style | High-speed universal |

| Variable Speed | Without Variable Speed |

| Transport Package | Pallet |

| Specification | all size |

| Trademark | Shindah |

| Origin | China |

| HS Code | 8479 |

| Production Capacity | 1000 Sets/Year |

Product Description

WSD large flow sand mill new type adapts new diversion trench and sand disc to achieve much higher efficient wet grinding technology. High-efficient diversion-trench grinding disc and super-big centrifugal flow turbine can be distributed in grinding chamber preferably.Centrifugal wheel is designed specially,under high line-speed,adopting centrifugal principle,centrifugal wheel can throw grinding medium and large particles material to the outside of filter. This will ensure much more working life of filter and make larger particles material be grinded in chamber repeatedly. This technology solves the problem that filter is plugged up easily. Adopts centrifugal-wheel style filter to increase flow rate and to separate grinding medium safely, if for larger flow separation system,it can work in much higher efficiency.

Disc of centrifugal grooves

Specially designed centrifugal wheel

Special designed large area of screen mesh

Eliminate invalid radial force of the cavity

All material of grinding chamber is replaceable

All easy-damaged parts can be replaced individually

Special disc and shaft with thrust

Special centrifugal type screen

Features:

- With high flow dynamic separate system and high efficient grinding system the solid particles can be ground down to sub-micron meter or sub micron meter range with concentrated particle size distribution.

- The mill stand is welded as a whole and the key parts of the mill such as double action mechanical seal, bearing, frequenter,feeding pump and belts are high quality products with international or domestic famous brands.

- The grinding system is formed by high wear resistance alloy which suits for the use of solvent based products.

- With the stretch lead rail, the grinding chamber and the chamber cover can move easily to favor the maintenance of the mill.

- The enhanced gap separator is used with increased flow area for higher viscosity product.

6. With above deploys and optimization, the quality of the ground product is improved and the production capacity is increased ( comparison to the mill with same type and same size, the production capacity can be increased to 20 - 30%), and the reliable and stable operation of the mill is realized

ApplicationApplicable for automobile paint, steelroll paint, corrosion-proof paint, wood paint, screen printing ink, Gravure ink, textile pigment, TiO2 powder, Pharmacy, Pestide, Copper Slurry, Titanium oxide etc

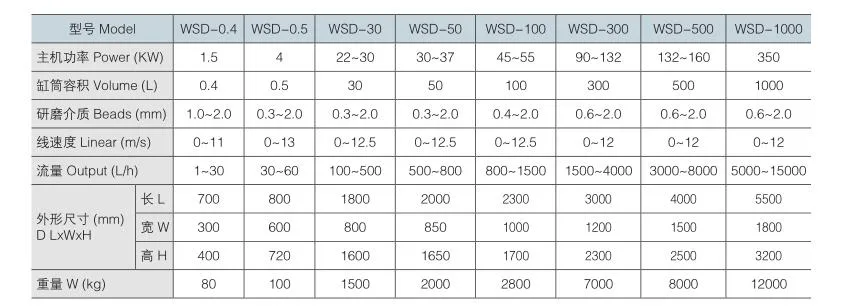

Product Parameters

Packaging & Shipping

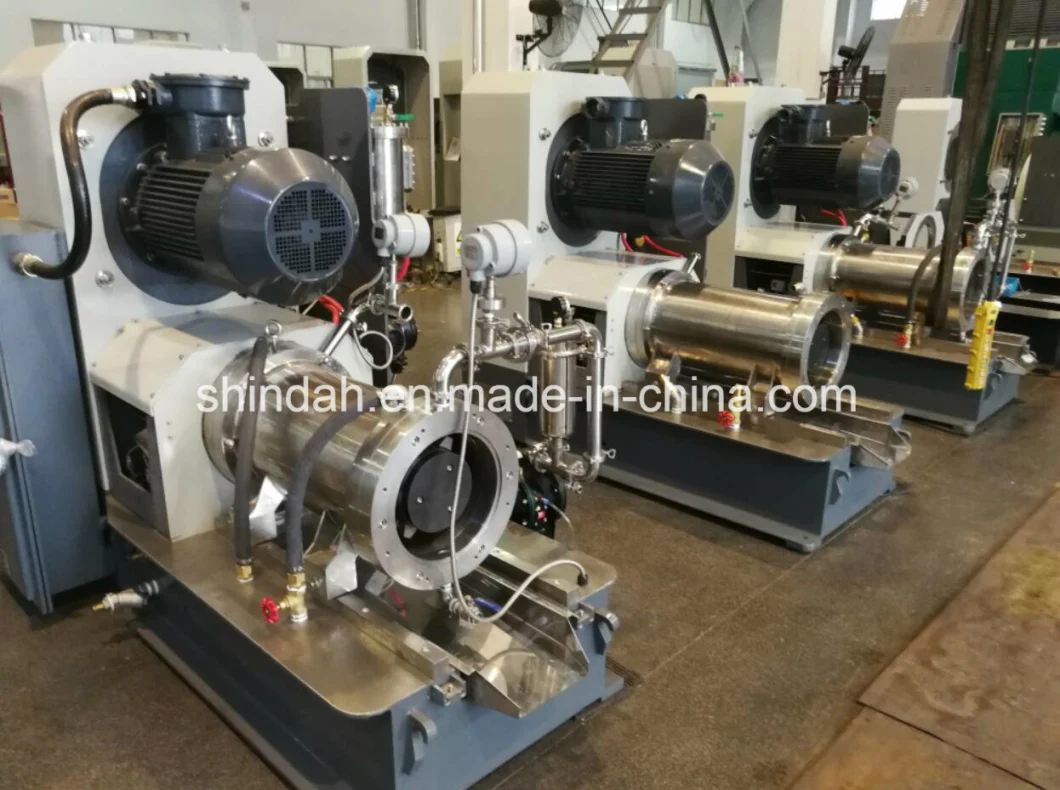

we make bead-grinding mill since 2003.

Strict quality control.

Fast delivery time.

Good after-sales services.

Reasonable prices.

welcome to send your inquiries. Look forward to working with you!