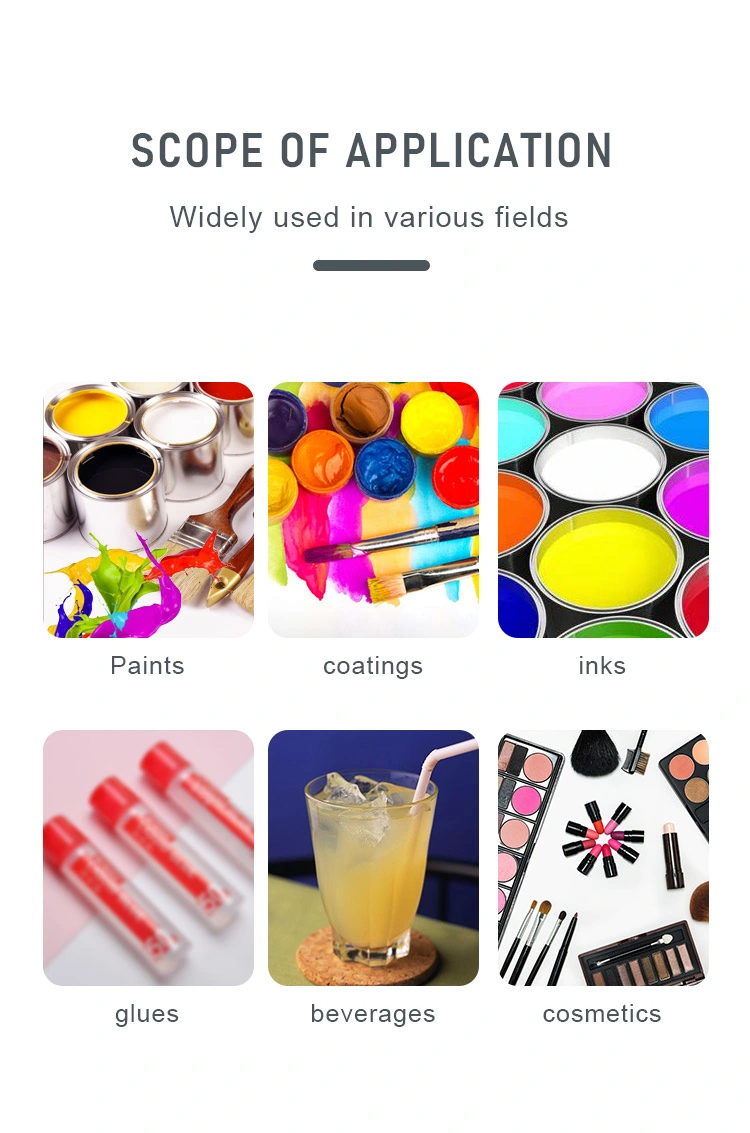

High Speed Disperser Industrial Mixer Liquid Detergent Mixer Adhesive Paint Pigment Inks Mixing Machine

Basic Info

| Model NO. | 1.5kw 3kw 7.5kw 11kw 15kw 22kw |

| Certification | CE, ISO |

| Application Area | Chemical |

| Layout Type | Verticle |

| Mixing Drum Shape | Disc |

| Additional Capabilities | Milling |

| Operating type | Cycle Operating |

| Condition | New |

| Product Name | Mixer |

| Function | Mixer Blender |

| Material | Stainless Steel 304 / SUS316L |

| Speed | Frequency Conventer Control |

| Transport Package | Machine Generally Packed in Standard Plywood Case |

| Trademark | KEDA |

| Origin | Laizhou, Shandong, China |

| HS Code | 8479820090 |

| Production Capacity | 99 Units/Month |

Product Description

| High Speed Disperser Industrial Mixer Liquid Detergent Mixer Adhesive Paint Pigment Inks Mixing Machine |

Product Description

Detailed Photos

The machine consists of five parts: hydraulic system (hydraulic lifting type), main drive, mixing system, guiding mechanism and electric control box. The parts are compact and reasonable. The type of dispersing disc has flat disc zigzag, three-finger paddle, disc, etc., and can be selected according to the process. The host adopts electromagnetic speed control or frequency conversion speed control, stable and strong operation, suitable for various viscosity; hydraulic and mechanical lifting forms, free lifting and rotation, adapting to various positions; general explosion-proof configuration, safe and reliable, simple operation and maintenance; continuous production Strong, the materials can be quickly dispersed and dissolved, the dispersion effect is good, the production efficiency is high, the operation is stable, and the installation is simple. There are different functions and models for the viscosity and production volume of different materials.

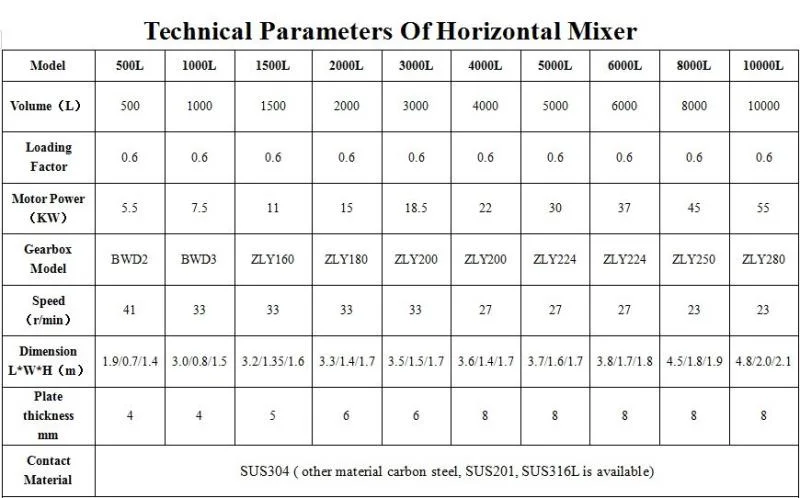

Product Parameters

Product application

Certifications

Packaging & Shipping

Company Profile

Our Advantages

We can ensure customers can always reach us. Customers get more benefit and interests from us, as we always consider and do anything, standing in customer's point of view. Customer can get cost-effective machinery from us: Under the same quality, we are committed to give customers a more reasonable price; For same price, we fight for higher quality. Customer can do the purchase and use machine without worries: Under the increasingly competitive environment, we pay more attention to the product's quality than the price. All customers will be treated with respect and sincere: We sincerely welcome all the customers, no matter facing middlemen or end users.