Category

Stainless Steel Mixing Vessel for Injection Liquid Bottom Tank

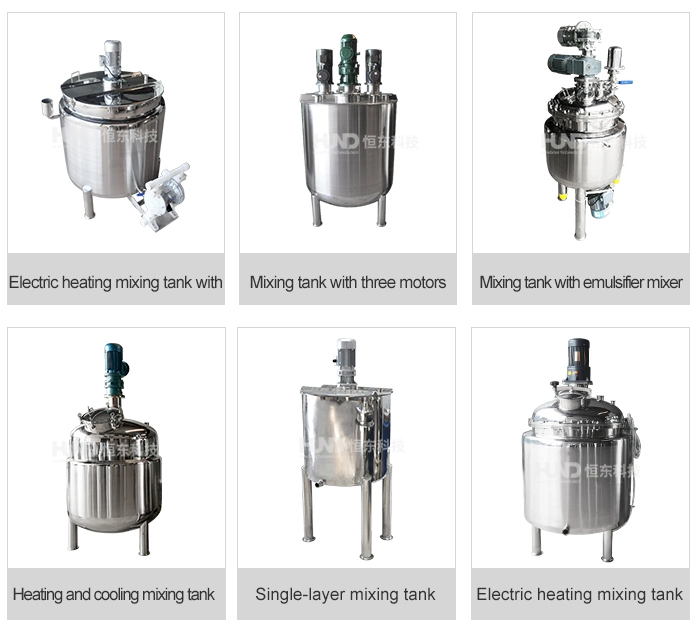

Tag:Stainless Steel Mixing Vessel for Injection Liquid Bottom Tank Magnetic agitation tank is composed of tank body and

Basic Info

| Model NO. | CLB |

| Layout Type | Verticle |

| Mixing Drum Shape | Conical |

| Additional Capabilities | Milling |

| Operating type | Continuous Operating |

| Condition | New |

| Material | SS304/SS316(L) |

| Voltage | 220V/380V/415V, 50/60Hz, 3phase |

| Power | 0.2-7.5kw |

| Motor | ABB/Siemens/Domestic |

| Speed | 120-1400rpm |

| Heating Method | Electric.Steam |

| Volume | 50-100000L |

| Pressure | <0.6MPa |

| Thickness | 2-10mm |

| Usage | Pharmaceutical, Chemical, Food, Cosmetic, Dairy, etc |

| Transport Package | Plywood Case |

| Specification | Customized |

| Trademark | HUNDOM |

| Origin | Guangzhou |

| HS Code | 8479820080 |

| Production Capacity | 100 Set/Sets Per Month |

Product Description

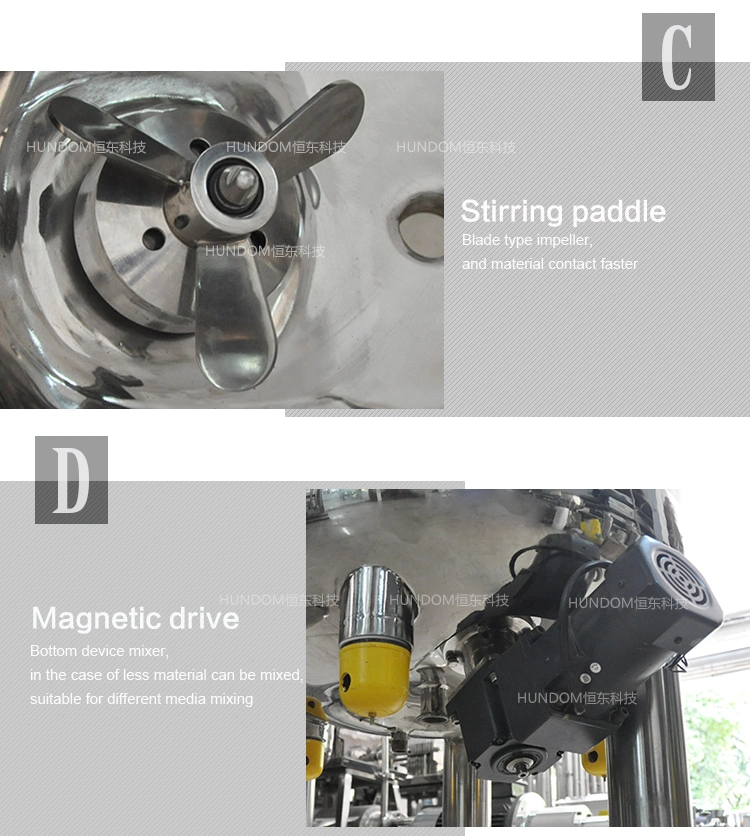

Tag:Stainless Steel Mixing Vessel for Injection Liquid Bottom TankMagnetic agitation tank is composed of tank body and a magnetic agitator.All the parts are made of high quality acid resistant stainless steel 304 or 316 and conform to GMP standard.The inner surface adopt mirror polish.The tank bottom use arc design which makes no dead angle of the tank.The inlet design makes a continuous filling possible the outlet design is good for discharge process.TRhe structure of tank adopt oval tank top and standard tank jacket.There is a magnetic agitator at the bottom,the agitator has the advantage of small distance from the tank bottom,low requirements of liquid level.As a result,there is no precipitation problem and solve the problem of top mixer requires a minimal liquid level.

Advantage

1. Silence seal (separation sleeve) instead of dynamic seal (driven shaft),which can completely solve the leaking, problem of mechanical seal.2. Simple structure,low maintenances cost, easy for disassemble ,easy for cleaning,no dead spot.3. Bottom entry mixing, can work under little liquid material,the special impeller can be applicated for stirring and mixing for various materials.4. Standard design makes it's quality spare parts am be interchanged on different mixers.

Application

Maindly be used in stainless steel reaction tanks, fermentation tank,feeding tank. storage tanks mixing for manufacturing following material: Infusion solutions, Small injections,,vaccines, blood products, insulin, oral liquid,etc.

Technical Parameters

| Model | Power(kw) | Volume(L) | Speed(r/min) |

| CLB-20 | 0.2kw | 50-200L | 120-1400 |

| 0.4kw | 50-200L | ||

| CLB-40 | 0.55kw | 200-500L | |

| 0.75kw | 200-500L | ||

| CLB-60 | 1.1kw | 500-1000L | |

| 1.5kw | 500-1000L | ||

| CLB-80 | 1.5kw | 800-2000L | |

| 2.2kw | 800-2000L | ||

| CLB-100 | 3kw | 1500-3000L | |

| 4kw | 1500-3000L | ||

| CLB-120 | 4kw | 2000-5000L | |

| 5.5kw | 2000-5000L | ||

| CLB-140 | 7.5kw | 3000-100000L |

About HUNDOM

Guangzhou Hundom Machinery Equipmenthas been manufacturing colloid mill, jacketed kettle, rotor pump, mixing tank and other machinery equipment for 14 years , putting quality as our first consideration. We own a team with rich experience in the field, if you have any question, contact us for the professional answer.

Guangzhou Hundom Machinery Technology.Add:No. 115, No. 7, Haina Industrial Park, Shibi Street, Panyu District, Guangzhou City, Guangdong Province, ChinaSales:ShumTel:+86-020-89081205Mobile:+86-138-2213-4643Welcome to visit our factory !