Steel High Viscosity Molasses Syrup Making Machine Mixing Tank with Lobe Pump Inline High Shear Mixer

Basic Info

| Model NO. | ACE-JBG-A137 |

| Certification | CE, ISO |

| Application Area | Food, Medicine, Chemical Industry |

| Layout Type | Verticle |

| Mixing Drum Shape | Paddle Mixer/Homogenizer / Anchor Mixer / Impeller |

| Additional Capabilities | Milling, Mixing Tank |

| Operating type | Mixing and Heating |

| Condition | New |

| Motor | Domestic/ABB/Siemens |

| Material | SUS304, SUS304L, SUS316, SUS316L, Ti |

| Voltage | 380V/ 3pH / 50Hz or Customized |

| Speed | 1-2800r/Min |

| Structure | Single/Double Jacket/Three Layers |

| Insulation Material | PU Foam / Rock Wool |

| Surface Finish | Matt Polish or Mirror Polish |

| MOQ | 1 Set |

| Control | Button or PLC (Simens, or Others) |

| Vacuum | Vacuum Pump |

| Heating Method | Steam, Gas, Electric |

| Advantage | High Quality and Low Price |

| After-Sales Service Provided | Online Support, Video Technical Support |

| After Warranty Service | Video Technical Support, Online Support |

| Transport Package | Tandard Wooden Packing as Export |

| Specification | Customized |

| Trademark | ACE |

| Origin | Wenzhou, Zhejiang, China |

| HS Code | 8479820090 |

| Production Capacity | 50sets Per Month |

Product Description

Custom Made 50L- 30,000L Mixing tank, 20 Years Of Experience. Reasonable Price And Best Service, CE Certificated Products.15-30 day fast delivery.Please Contact us for the offer.

Product Description

| Mixing tank (Accept customized) | |||

| Profile/type | Single layer tank | Double layer tank | Three layer tank |

| Material | SS304 or SS316L | ||

| Volume | 50L-30T (Customized) | ||

| Tank Type | Vertical type/Horizontal type/Mobile type | ||

| Structure | one layer | Inner layer+jacket | inner layer+jacket+insulation |

| heating way | Electric/Steam Heating | ||

| Inside Finsh | Mirror polished Ra<0.4um<> | ||

| Outside Finish | 2B or Satin Finish | ||

| Stirrer type | impeller, Anchor , Turbine , High shear, magnetic mixer, Anchor mixer with scraper | ||

| Power | 0.55~55KW | ||

| Voltage | 110V~480V | ||

| Top Head type | Dish top, Open lid top, Flat top | ||

| Bottom type | Dish bottom, Conical bottom, Flat bottom | ||

| PARTS DETAILS | 1.Quick open manhole / Pressure manhole | ||

| 2.Various types of CIP cleaners | |||

| 3.Sterile respirator | |||

| 4.Adjustable Legs | |||

| 5.Inlet and Outlet sanitary valve | |||

| 6.Thermometer (According to customer requirements ) | |||

| 7.Paddle blender .(According to customer requirements) | |||

| 8.Liquid level meter and lever controller (According to customer requirements) | |||

| 9.Ladder | |||

| Application | Food, Beverage, pharmacy, biological,honey, chocolate, alcohol ,chemical industry etc | ||

| We can customize the mixing equipment according to customer requirements. | |||

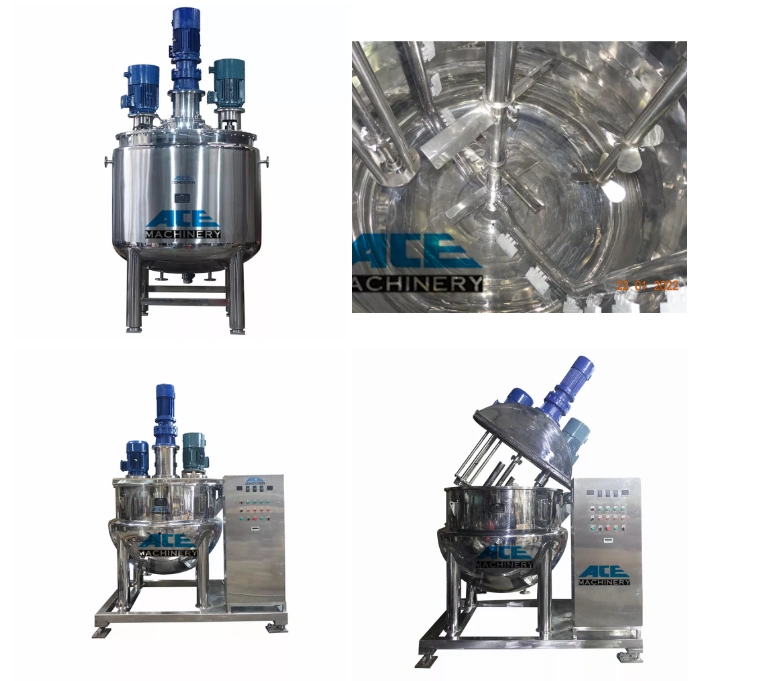

Have different kinds of agitators: ( Other Stirrer can be customized )1, Bottom magnetic agitator with propeller impeller, speed from 50-400rpm or 50-800rpm. this kind of agitator is mixing thin viscosity , such as eyedrop, injection, CIP liquid, water, etc.2, Top mechancial agitator with propeller impeller, speed at fix 71rpm or adjustable 20-200rpm or special requirement. this kind of agitator is mixing syrup, injection, blood, oral liquid, culture media, etc.3, Top mechanical agitator with anchor or frame impeller, speed is from 10-70rpm. it is mixing higher viscosity , such as sediment or viscosity oral liquid, etc.4, Top emusification homogenizer, speed max 2900rpm for small vessel, 1480rpm for bigger tank. this kind of agitator is mixing most high viscosity , such as suspension, oil, fat emulsification , etc.5, Bottom emusification homogenizer, speed max 2900rpm for small vessel, 1480rpm for bigger tank. this kind of agitator is mixing most high viscosity , such as suspension, oil, fat emulsification , etc.

Detailed Photos

Packaging & ShippingWe are experienced in the whole packing and shipping process,and we will be responsible for any damage made during shipping and send clients replacements for free.* Sufficient inner protection with different materials, including bubble bag, foam board and others.* Qualified wooden package or carton for different products or as customer require* Strict packing process to ensure the safety and completeness of the goods

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in plywood case or carton package for small parts.If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.Q2. What is your terms of payment?A: T/T in advance, 30% as deposit, and finish 70% balance payment before delivery.We'll show you the photos of the products and packages before you pay the balance.Q3. What is your terms of delivery?

A: EXW, FOB, CIF, DDU.Q4. How about your delivery time?

A: Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time dependson the items and the quantity of your order.Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.Q6.Do you test all your goods before delivery?

A: Yes, we have 100% test before deliveryQ7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.