Phosphate Gypsum Manganese Feldspar Clay Gypsum Gold Copper Iron Ore Silica Sand Quartz Limestone Ball Mill

Basic Info

| Model NO. | 900*1800, 1200*3000, 1500*4500, 2200*7000 |

| After-sales Service | 24hours |

| Warranty | 2 Years |

| Application | Mineral Operation |

| Certification | ISO |

| Customized | Customized |

| Automatic Grade | Automatic |

| Liner | Steel, Ceramic, Rubber |

| Capacity | 0.5-100t |

| Package | Container, Flatrack, in Bulk, Standard |

| Power | Min. 18.5kw |

| Certificate | ISO9001 |

| Grinding Material | Ore, Ceramic, Cement, etc. |

| Installation | Guide by Engineer at Site |

| Service | Whole Using Life |

| Transport Package | Suitable for Ocean Shipping |

| Specification | ISO9001: 2000 |

| Trademark | HONGJI |

| Origin | China |

| Production Capacity | 100 Sets/Month |

Product Description

Product Description

Product Application:

Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.Main Features:

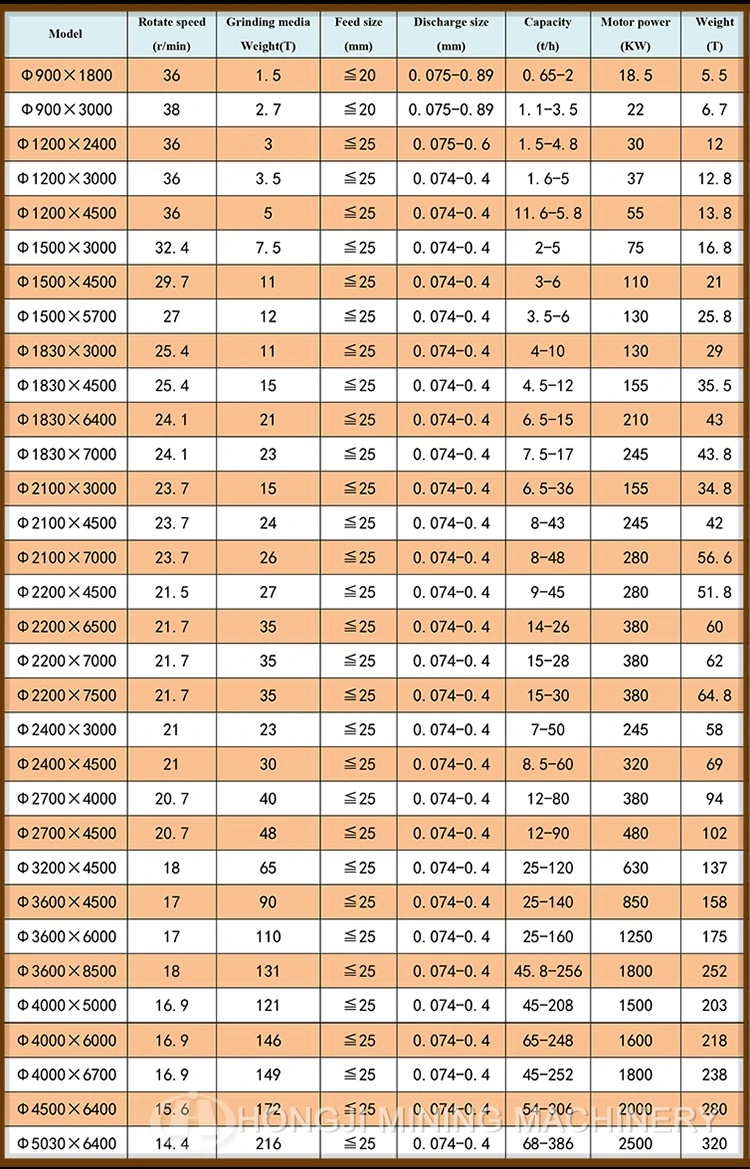

1) This Ball mill machine changes the intrinsic grinding mill structure.2) Its body and ground plank are an integral whole. So when fixing, it can be lowered on a plane surface once only.3) Use double tiered roller axletree with centripetal spherical surface as the support of the host axletree can reduce energy cost by 30%.4) The intrinsic grille pattern forcing evacuation is instead by over fall pattern controlling one. This can improve the milling of the granule and the quantity dealt with is reduced by 15-20%.Product Parameters

Working principle:

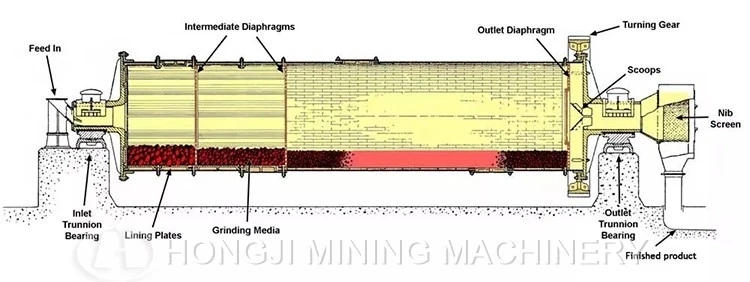

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.Ball mill is widely used for medium and fine crushing (sand making) for various hard and brittle materials such as rocks, cement clinker, quartz, iron ore and concrete aggregates, grinding materials, refractory materials, etc.Our Advantages

| 1 | High production capacity and crushing ratio; |

| 2 | Low power consumption, uniform particle size; |

| 3 | Simple structure, easy to operate; |

| 4 | Low investment cost, big profit; |

| 5 | Perfect services, both before-sales services and after-sales services. |

Packaging & Shipping

Success Case

Company Profile

Henan Hongji Mine Machinery is a reputed manufacturer and joint-stock enterprise with import & export rights and mainly produces large and medium-sized mining machinery, metallurgy machinery and building material equipment. We were founded on August 7th, 1996 by restructuring and setting up 4 branch companies and a research institute. Customers' need is what we are trying to create. Customer satisfaction is what we are seeking. Over the last couple of decades, Hongji people have created continuously, transcending ourselves and insisting on the concept of "Development is of overriding importance". Develop the brand with quality. Promote the brand with service. We, Hongji people, are forging ahead for first-class brand with innovative spirit and do our best to contribute to the national industry.

Certifications